In industrial production, verification of grease presence on metal connectors is crucial for ensuring the proper function and reliability of electro-mechanical joints. Grease prevents corrosion, improves conductivity and extends connector life, so it is essential to ensure it is present in the right places.

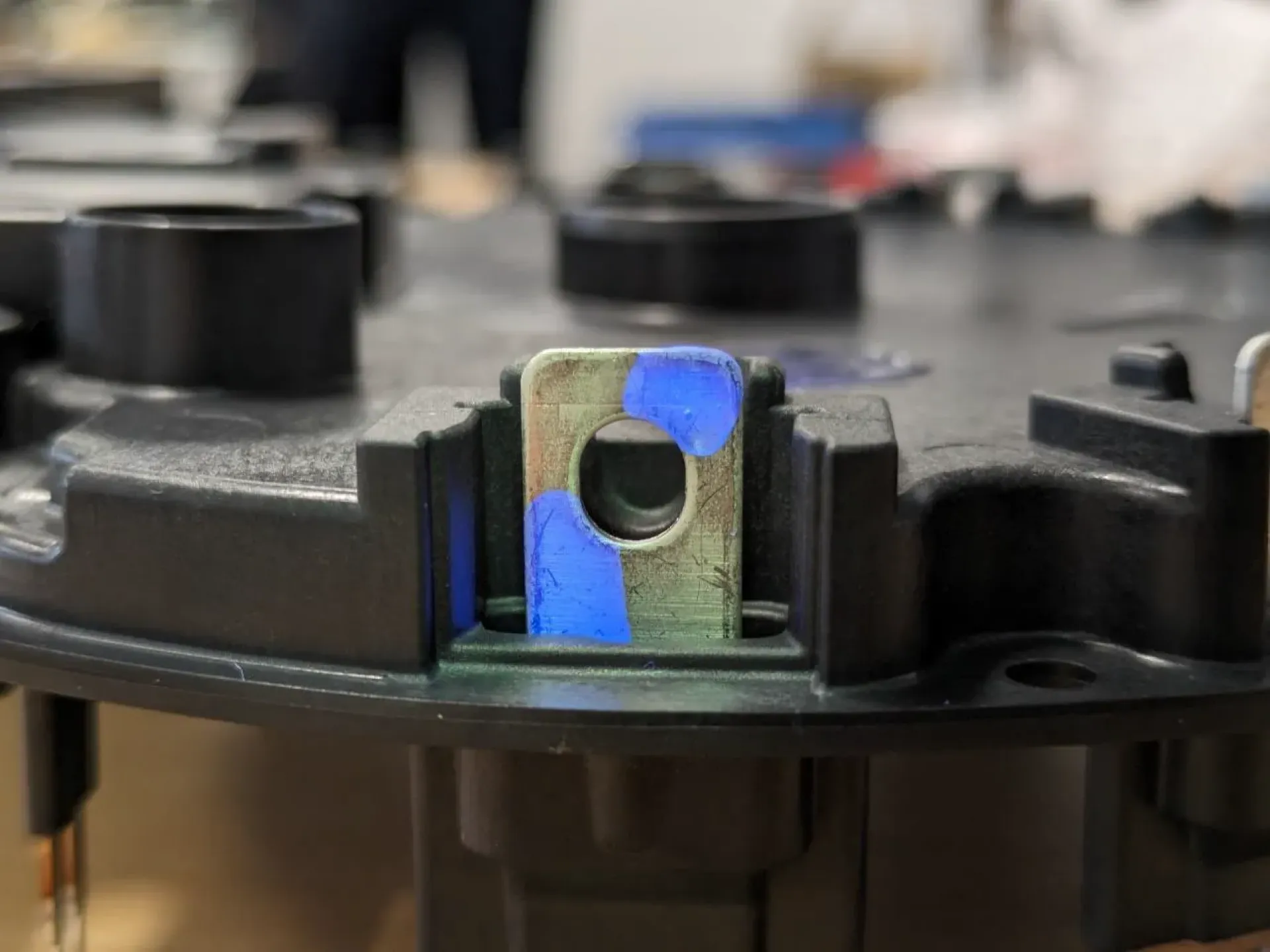

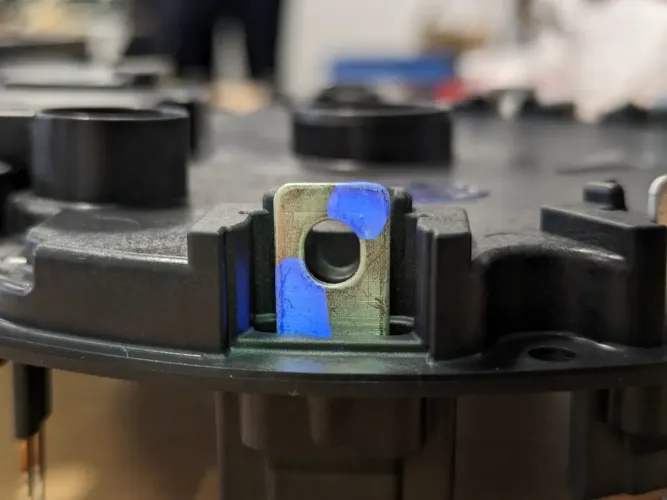

This system uses a smart camera combined with powerful, direct UV SmartView lighting, enabling precise detection and analysis of applied grease under varying production conditions.

- A smart camera – an advanced optical system with high resolution for detecting surface treatments.

- Powerful direct UV SmartView lighting – illuminates the connector at a specific wavelength optimizing the contrast of the applied grease.

The system performs automatic verification of grease presence to ensure that:

- Grease is correctly applied on the defined areas of the connector.

- Visual detection is accurate enough to distinguish grease from surrounding materials.

- The system reacts in real time so as not to limit line capacity.

- Illumination of UV-sensitive materials – an optimal UV wavelength must be found that highlights the grease while minimizing disturbances.

- Distinguishing areas with grease – the system must differentiate correctly applied grease from surface irregularities.

- Analysis speed – inspection must be fast to remain fully compatible with the line.

- Use of direct, intense UV SmartView lighting that optimizes the contrast between the grease and the metal surface.

- A smart camera with suitable resolution enabling accurate analysis of each inspected connector.

- A combination of software tools to evaluate correctly applied grease and visualize it.

- Automatic detection of correctly applied grease on connectors.

- Identification of areas lacking sufficient grease, enabling subsequent application or rework.

- High analysis speed, so inspection does not limit line capacity.

- Areas with grease are graphically highlighted, enabling immediate evaluation of application quality.

- Areas without sufficient grease are marked, enabling quick process corrections.

- Data are automatically stored, enabling long-term monitoring of grease application quality.

This system leverages experience in UV lighting for highlighting sensitive materials, enabling precise, efficient and fast quality control of grease application.

Thanks to the intelligent combination of optical lighting, a camera system and software algorithms, maximum detection accuracy is ensured, minimizing production defects and optimizing the entire inspection process.