Modern industry requires precise quality control at every stage of production. One of the key steps is the inspection of the heat pump before dispatch, which ensures that all components are correctly assembled, securely fastened and meet the specifications.

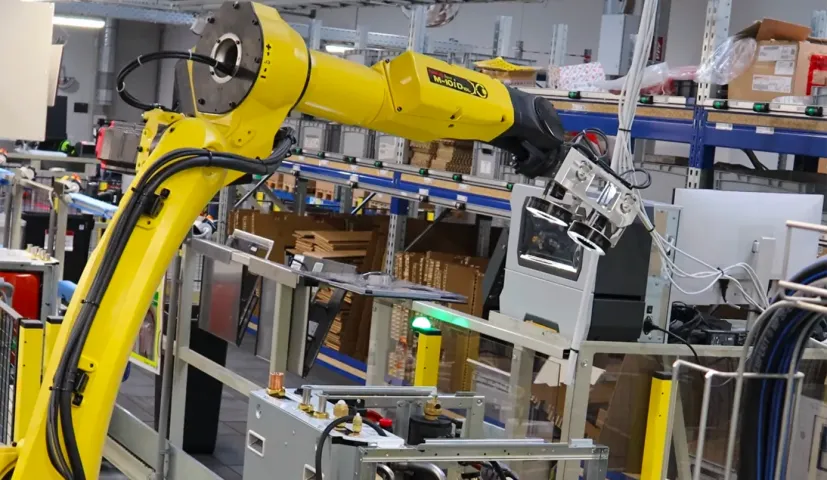

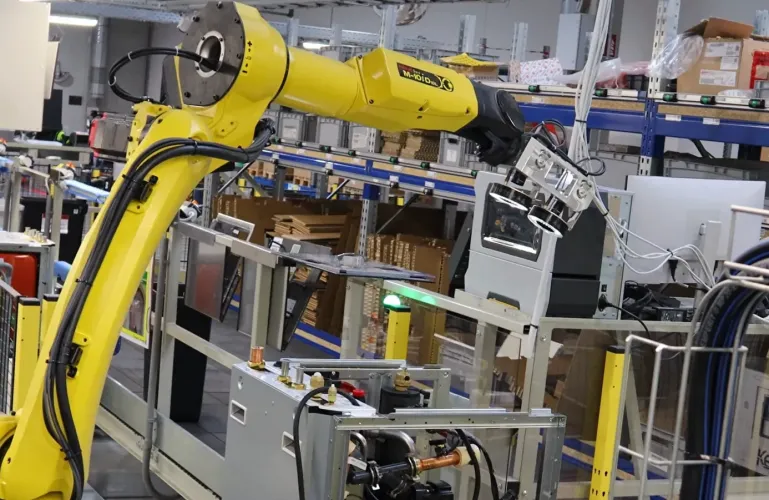

The inspection process uses a multi-camera system composed of 19 camera heads that capture the product from different angles. The system works in combination with a robotic arm, which enables a detailed inspection of the pump from multiple sides. To ensure consistent, high-quality images, different lighting principles are used to optimize the visibility of the inspected elements.

The software is based on AI algorithms, specifically Deep Learning, which enables advanced image analysis. Thanks to this, it is possible not only to detect the presence of components, but also to evaluate their correct placement and fastening.

The inspection includes several key checks using Deep Learning algorithms that recognize correct fastening even when positions differ:

- Check of the presence and tightening of clamps, which prevents them from loosening during operation.

- Check of clip presence

- Check of correctness and placement of labels on the product, which ensures proper identification of components.

- Check of labels on the product packaging, so the pump is correctly marked for transport.

- Reading information from labels using AI OCR tools.

One of the main challenges is the complexity of multi-angle inspection provided by the robotic arm. The product is inspected in a pre-defined time, which requires optimizing the inspection speed while maintaining high accuracy.

Conventional inspection methods often cannot evaluate whether clamps are properly tightened because their position may vary. However, AI algorithms can recognize whether a clamp is correctly fastened, regardless of its exact position.

- A robotic arm for manipulating and changing the product position during inspection.

- Multi-camera inspection, which allows recording from several locations and angles simultaneously.

- Software based on AI algorithms that learn to recognize defects and inconsistencies in component fastening.

- Stable and optimized lighting that minimizes poor images caused by glare or shadows.

With this system we achieved precise visual inspection of the presence and placement of tracked elements.

After scanning, automatic evaluation of the results is performed and displayed on the computer monitor:

- Each of the 19 clips is visualized on the screen with its status. Mismatches are highlighted in red, while matches in green.

- Visualization of the presence, correctness and content of labels on the product and its packaging.

This multi-camera inspection of a heat pump significantly increases inspection efficiency and ensures higher accuracy compared to conventional methods. Thanks to AI algorithms, the reliability of detecting properly fastened components has increased, minimizing potential defects before delivery to the customer.

At the same time, the supplier’s long-standing expertise in machine vision has been leveraged, which is reflected in the quality of the final solution.