The modern automotive industry places high demands on the precision and quality of components used in vehicle interiors. The instrument panel carrier is one of the key elements whose dimensions and correct placement play a crucial role in assembly. This inspection system uses a 3D triangulation profilometer combined with a robotic arm to ensure precise presence checks and measurement of critical dimensions.

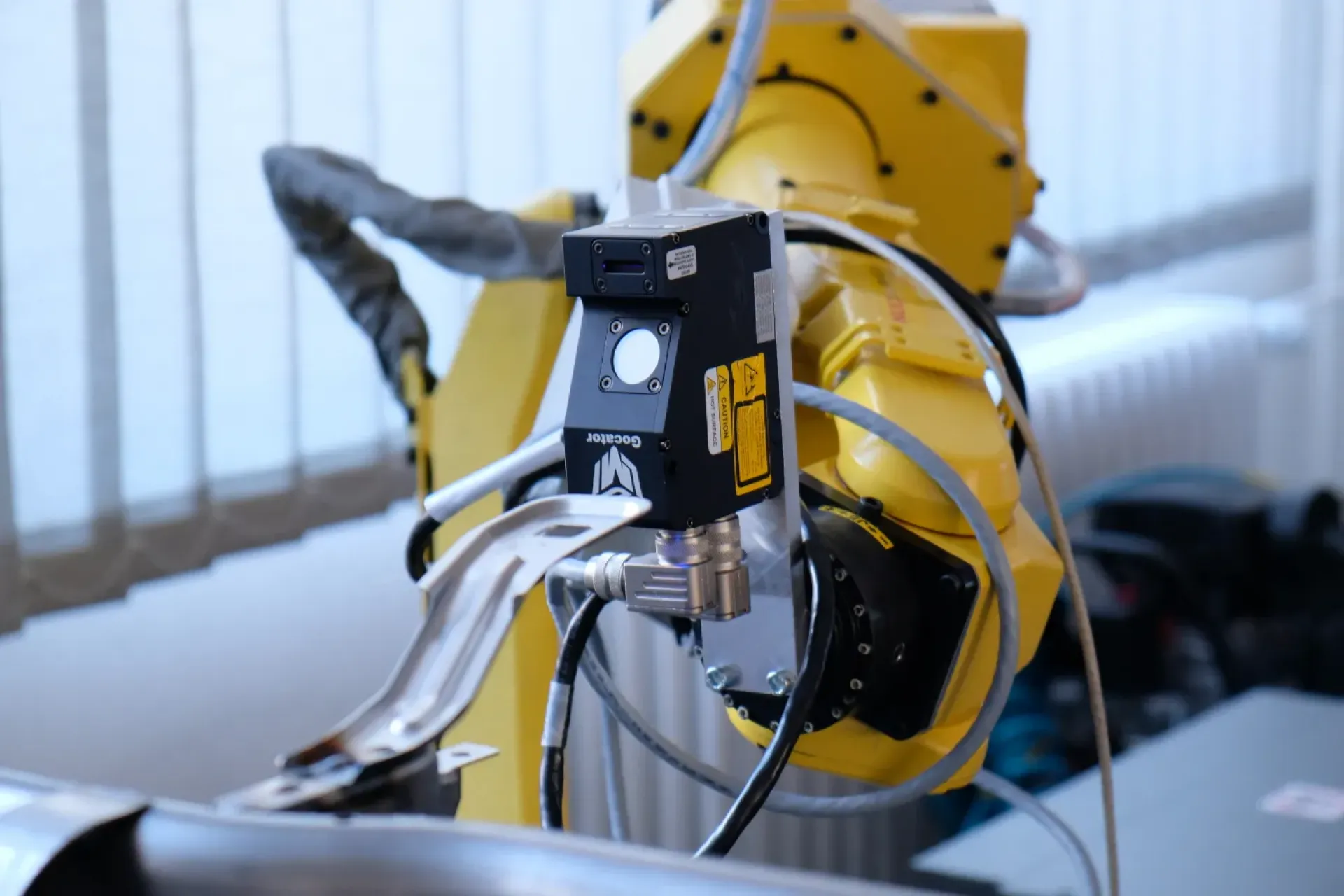

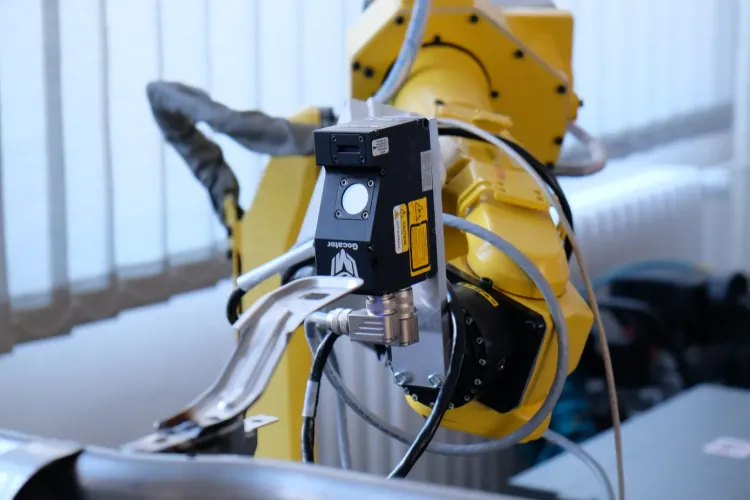

- 3D triangulation profilometer – an advanced optical device enabling accurate measurement and surface scanning.

- A robotic arm – provides flexible handling of the measuring head and motion around inspected features.

The application is designed for automated checks of the presence of key features and measurement of critical dimensions of the instrument panel carrier. The system must be able to:

- Identify all required components on the carrier.

- Ensure precise dimensional measurement of critical locations according to customer specification.

- Perform the inspection in a pre-defined time so the production flow is not disrupted.

- System calibration – ensuring the measuring device remains accurate even during long-term operation.

- Accurate measurement – some critical features have small tolerances requiring very fine scanning.

- Time limit for measurement – the system must enable quick scanning and result evaluation without delays.

- Robot parameterization – correct motion trajectory settings to avoid errors during inspection.

The entire inspection process is based on optical control using a 3D triangulation head mounted on the end of a robotic arm. This approach enables flexible measurement of different areas of the instrument panel carrier and precise identification of defects or deviations from required dimensions.

- Reliable presence checks of required features on the instrument panel carrier.

- Accurate dimensional measurement in line with requirements and defined tolerances.

- Optimized measurement time that does not affect production flow.

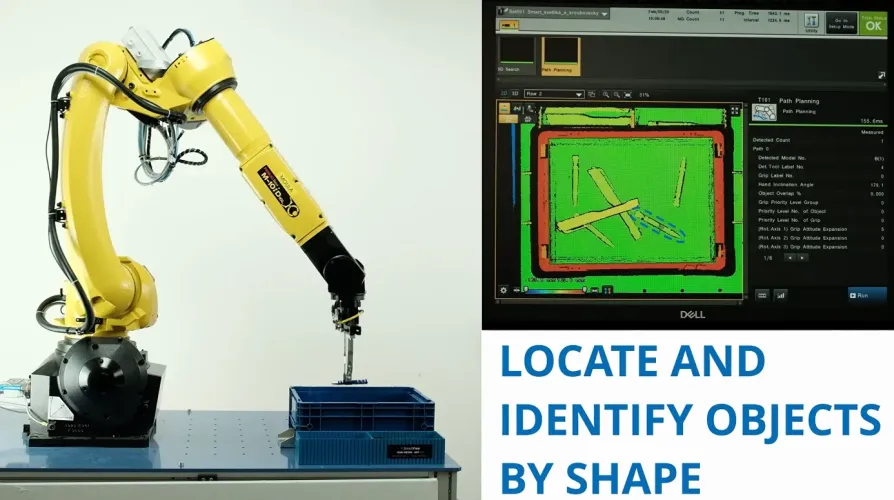

- Identification of critical feature presence is displayed graphically.

- Comparison of measured data with required values, enabling quick detection of deviations.

- Measurement history is recorded to track trends and analyze production quality.

This 3D inspection system for the instrument panel carrier uses advanced sensing and robot parameterization, enabling precise, fast and efficient inspection during production.

Thanks to specialization in 3D triangulation devices, a highly reliable application has been created.