Precise visual inspection of interior automotive parts is a key step to ensure high final product quality. The designed system uses SmartView lighting for defectoscopy, a robotic arm and a smart camera with AI algorithms to detect even the smallest surface defects such as scratches, paint defects, overpainted contaminants, dents or gouges.

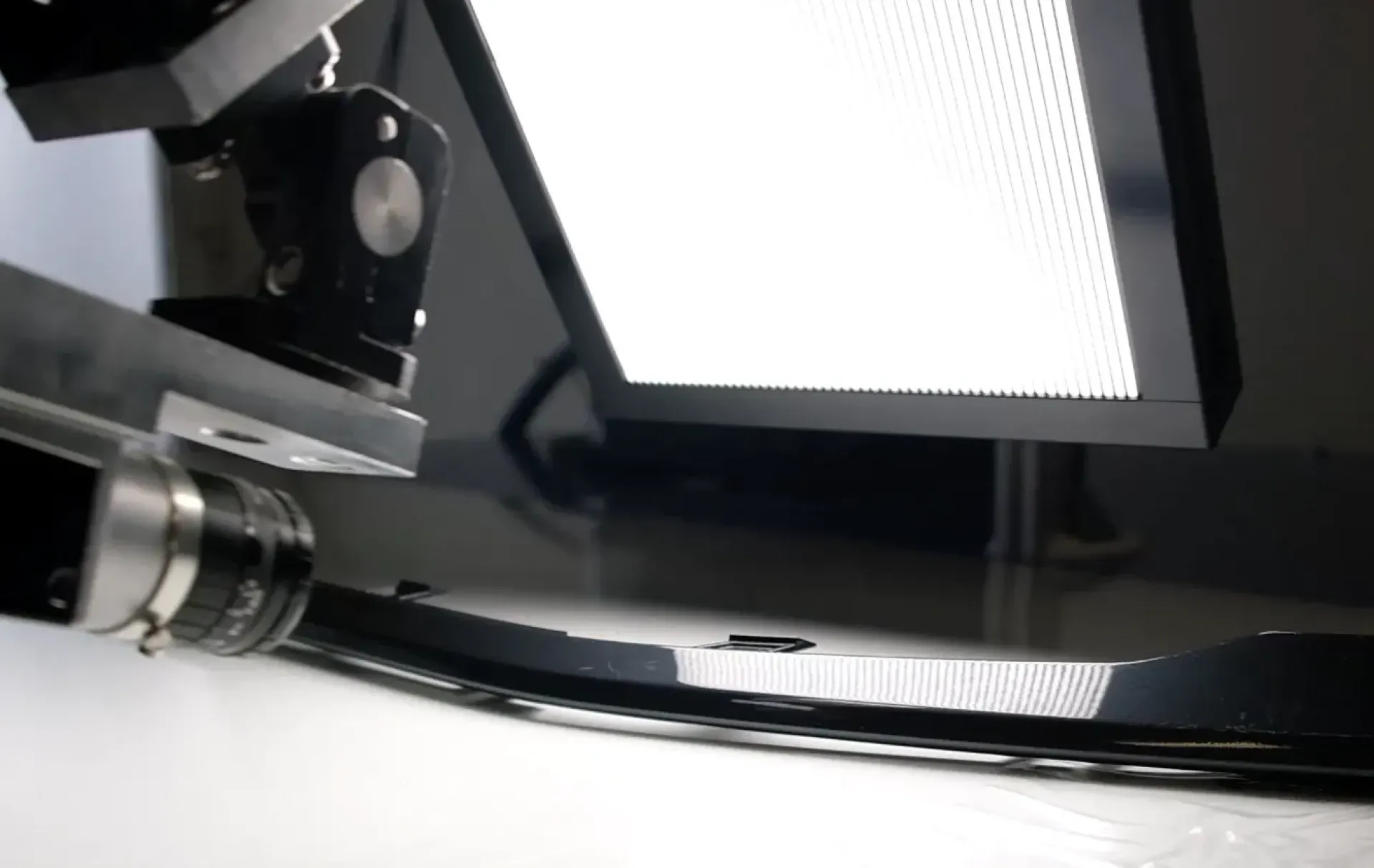

- SmartView lighting – optimized illumination enabling identification of defects even on glossy surfaces.

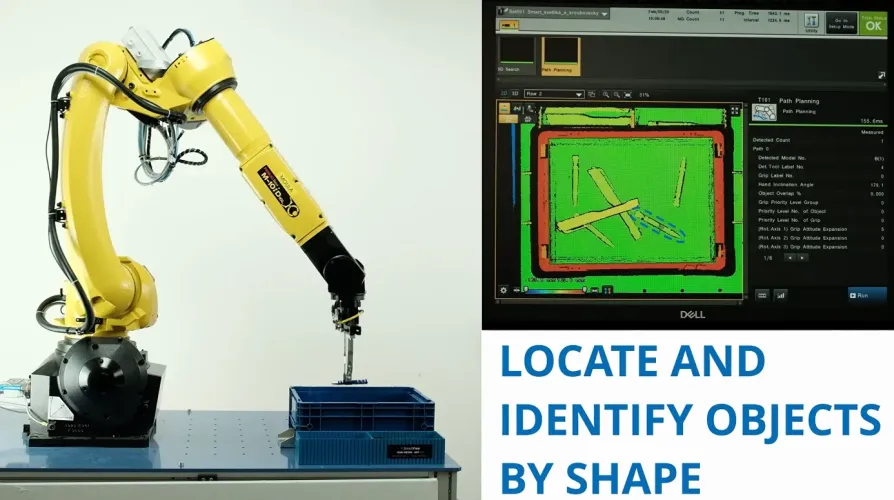

- A robotic arm – enables accurate imaging of parts from different angles.

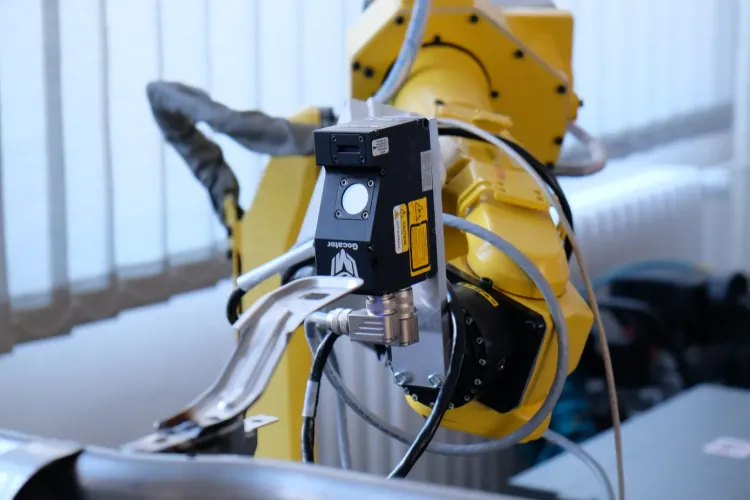

- A smart camera with AI algorithms – detects and classifies defects using machine learning.

The system performs a detailed inspection of surface defects on interior automotive parts. The process includes:

- Detection of scratches, paint defects, overpainted contaminants, dents and gouges using optical imaging.

- Categorization of defects based on their type and severity.

- Optical analysis to assign defects to the corresponding manufacturing processes or control measures.

- Glossy part surfaces – reflections and unevenness can complicate defect detection.

- Variable part geometry – inspection is performed on parts with concave and convex surfaces.

- Time optimization – the measurement must be completed within a time window defined by the customer.

- Differentiating individual defect types – AI algorithms enable accurate identification and categorization.

- A robotic arm for handling parts during inspection.

- A smart camera with AI algorithms that uses machine learning to detect and classify defects.

- Special SmartView lighting optimized for visual inspection of glossy surfaces.

Using defectoscopic SmartView lighting, a robotic arm and a camera system with AI algorithms achieved reliable detection of surface defects.

After the product is scanned, the data are automatically evaluated and displayed on the computer monitor. Results are visualized so users can quickly identify problem areas.

- Individual defects are visualized on the screen and color-coded.

- Data are automatically sent via FTP to external storage for archiving.

- Defects are classified into categories, enabling easy trend tracking and discovery of systematic issues in production.

The designed application sets new standards in optical quality control of automotive parts and contributes to improving the manufacturing process. The combination of a robotic arm, intelligent lighting and AI algorithms enables fast, accurate and automated inspection that would be difficult to achieve using traditional methods.

This project leverages long-standing experience in machine vision lighting, resulting in a highly effective solution for detecting surface defects in the automotive industry.