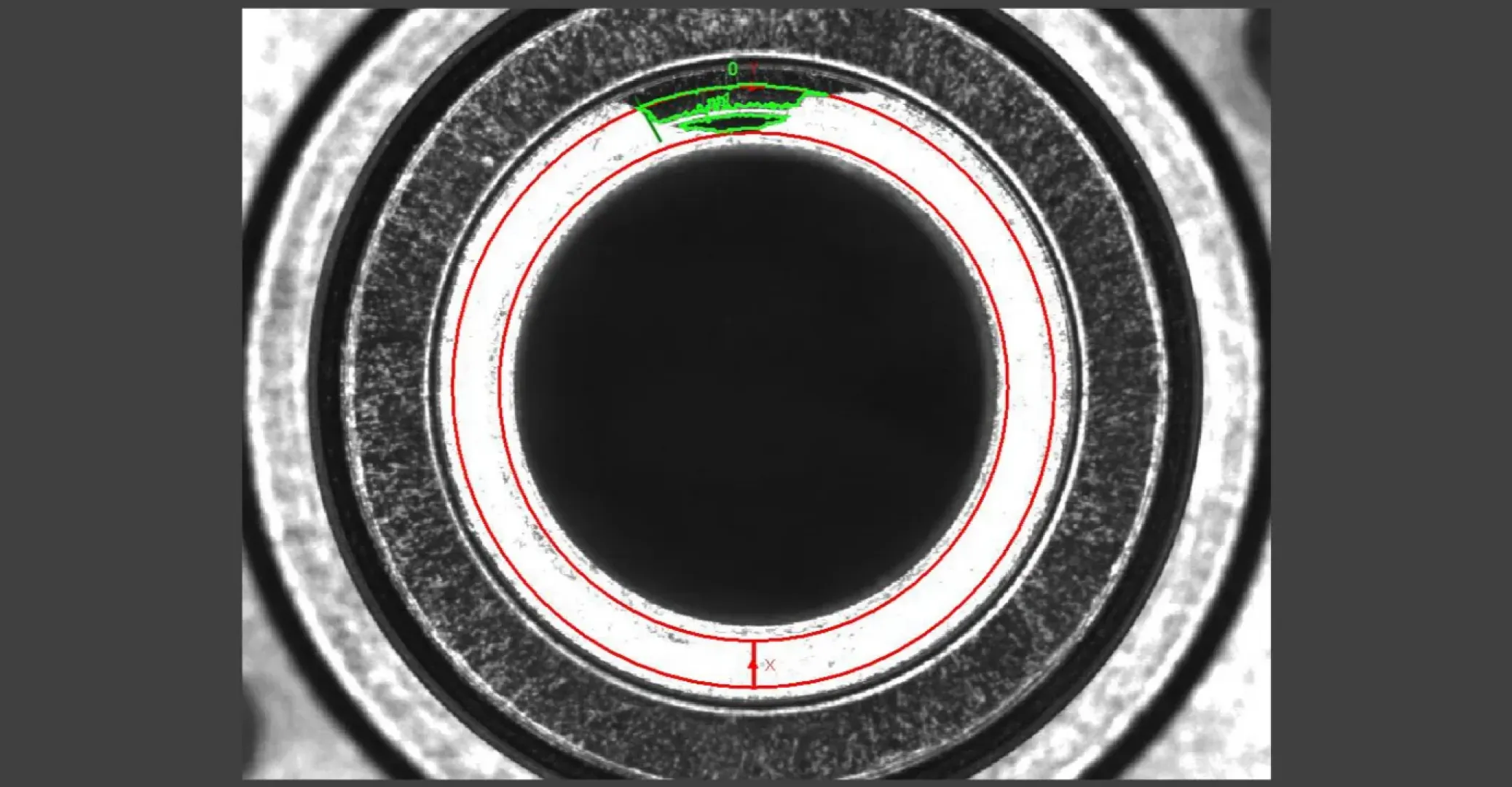

In precision manufacturing, quality inspection of brass rings is essential to ensure proper functionality. Any cracks, scratches, dents, missing sections or burrs can affect the mechanical properties of the part, leading to assembly problems or reduced service life.

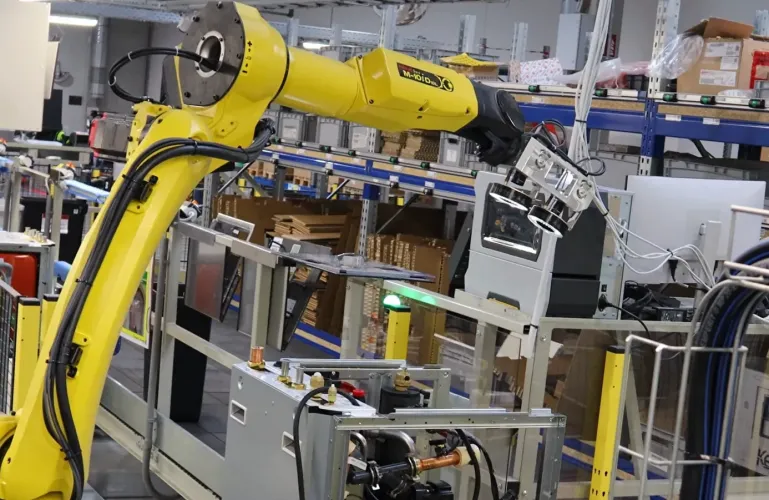

This system uses a PC-based vision system, SmartView lighting and a lens for detailed inspection, enabling precise defect detection, classification and analysis under varying production conditions.

- PC-based vision system with AI tools – advanced imaging technologies for defect detection and classification.

- SmartView lighting – homogeneous light optimized to highlight defects on metallic surfaces.

- Lens for imaging small defects – provides sufficient magnification to reveal small imperfections.

The system performs automatic defect detection on a brass ring to ensure:

- Identification of defined defects, including cracks, scratches, missing sections, dents and burrs.

- Classification of defects by type and severity for further processing.

- Analysis across the entire part surface, including parallel and conical surfaces tapering inward.

- Consistent and effective lighting enabling high-quality defect detection on reflective metal surfaces.

- Lens optimization to display even the smallest defects without distortion.

- Processing of defective areas using AI tools, as defects can vary and appear across different surface areas.

- Analysis speed that must be synchronized with the production line.

- SmartView lighting ensuring homogeneous light conditions for camera inspection.

- PC-based vision system with AI tools using machine learning to detect and classify defects.

- Lens for detailed inspection to achieve maximum image resolution and accurate detection of even small damage.

- Reliable defect detection on the brass ring across the entire camera field of view.

- Identification of a wide range of defects, including the smallest cracks or deformations.

- Seamless integration into production thanks to high detection and classification speed.

- Each ring is analyzed and visualized, with defective areas clearly highlighted.

- Defective rings are classified by damage type, enabling effective decisions about further processing.

- Data are automatically stored, enabling retrospective analysis of production quality and optimization of parameters.

This system leverages specialization in lighting for camera applications, enabling precise, efficient and fast quality control of brass rings.

Thanks to the intelligent combination of lighting, the camera system, the lens and AI algorithms, maximum detection accuracy is ensured, minimizing production defects and optimizing the entire inspection process.