In industrial processes it is crucial to ensure correct sealant application, especially on metal parts used in automotive and mechanical industries. This system uses a 3D triangulation profilometer combined with a robotic arm, enabling automated inspection of the height, continuity and presence of the applied sealant.

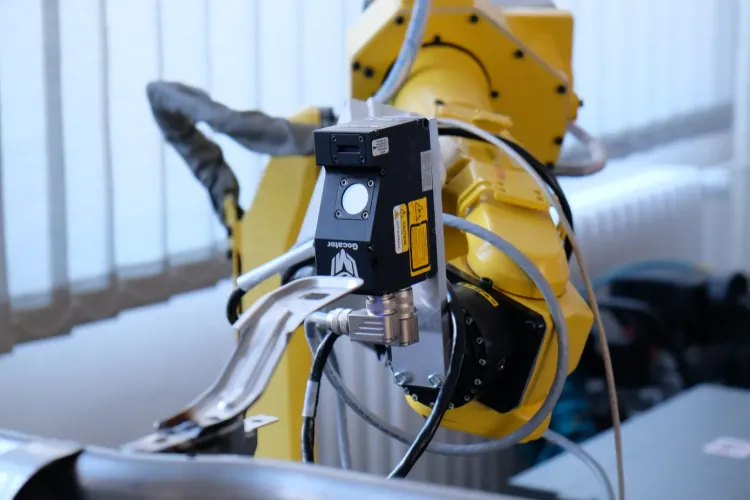

- 3D triangulation profilometer – enables precise measurement of sealant height and consistency.

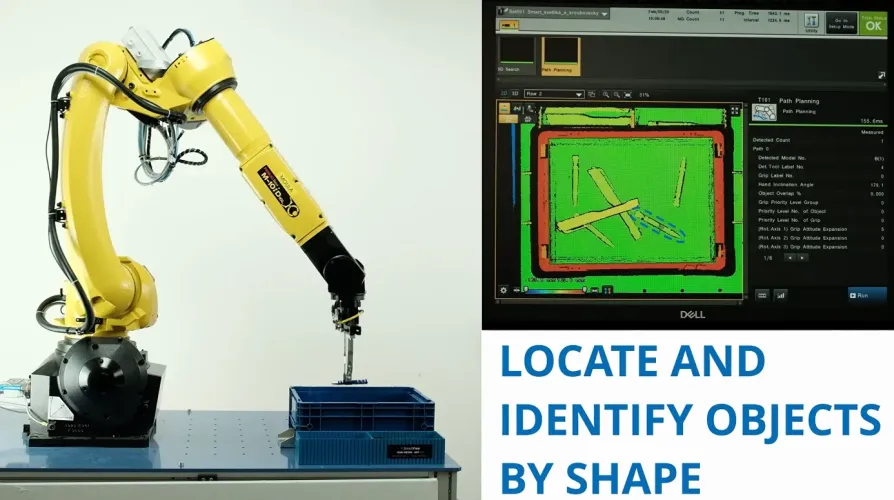

- A robotic arm – provides flexible manipulation and accurate movements of the sensing head.

The goal is to check sealant presence, its height and continuity on the metal part. The system must be able to:

- Detect correct sealant application on the inspected surface.

- Ensure precise measurement of sealant height according to required values.

- Evaluate sealant continuity – any breaks or uneven application can affect product quality.

- Perform the inspection in a pre-defined time to avoid interrupting production.

- System calibration – necessary to ensure stable, accurate measurement across conditions.

- Precise measurement of sealant height – even small deviations may require rework.

- Time constraints – inspection must not slow the production line.

- Robot parameterization – correct trajectory settings for maximum measurement efficiency.

Measurement is based on optical inspection using a 3D triangulation head mounted on the end of a robotic arm. This approach enables flexible, precise measurement of different areas of the metal part without physical contact. The system performs:

- Detailed scan of the applied sealant across the metal surface.

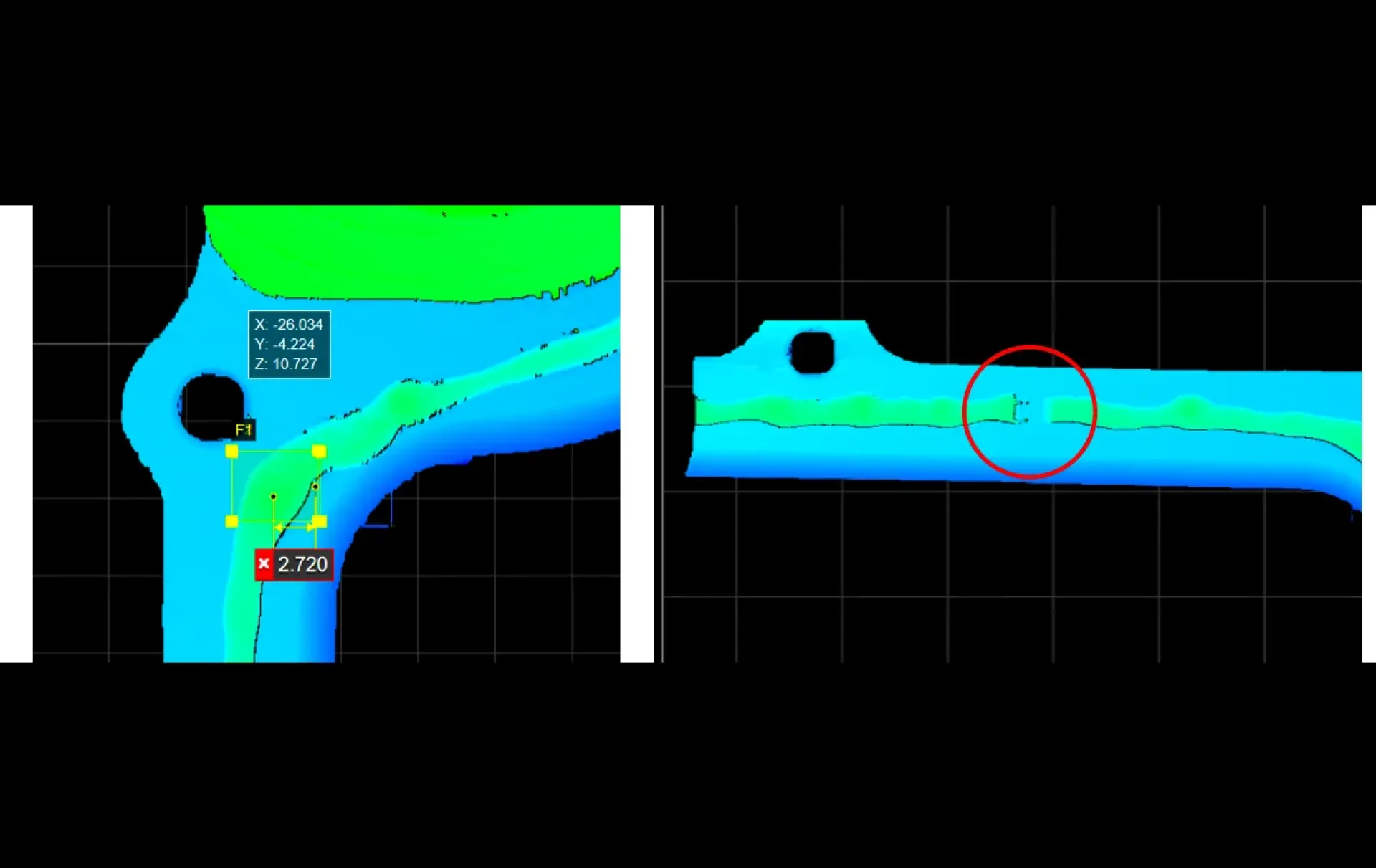

- Automatic analysis of sealant height and identification of deviations.

- Detection of sealant breaks, ensuring full coverage.

- Accurate verification of sealant presence and dimensions according to specifications.

- Reliable measurement of height and continuity, enabling quick defect identification.

- Optimized scanning and evaluation speed meeting production cycle times.

- Graphical display of sealant application, with clear highlighting of correct and faulty areas.

- Comparison of measured data with required values, enabling quick deviation identification.

- Automatic data storage for later analysis and quality tracking throughout production.

This system uses advanced sensing with 3D triangulation devices, enabling fast, precise and efficient quality control of the applied sealant on metal parts.

Thanks to expertise in robot arm parameterization, a highly reliable application was created that eliminates sealant application errors and contributes to overall production quality.