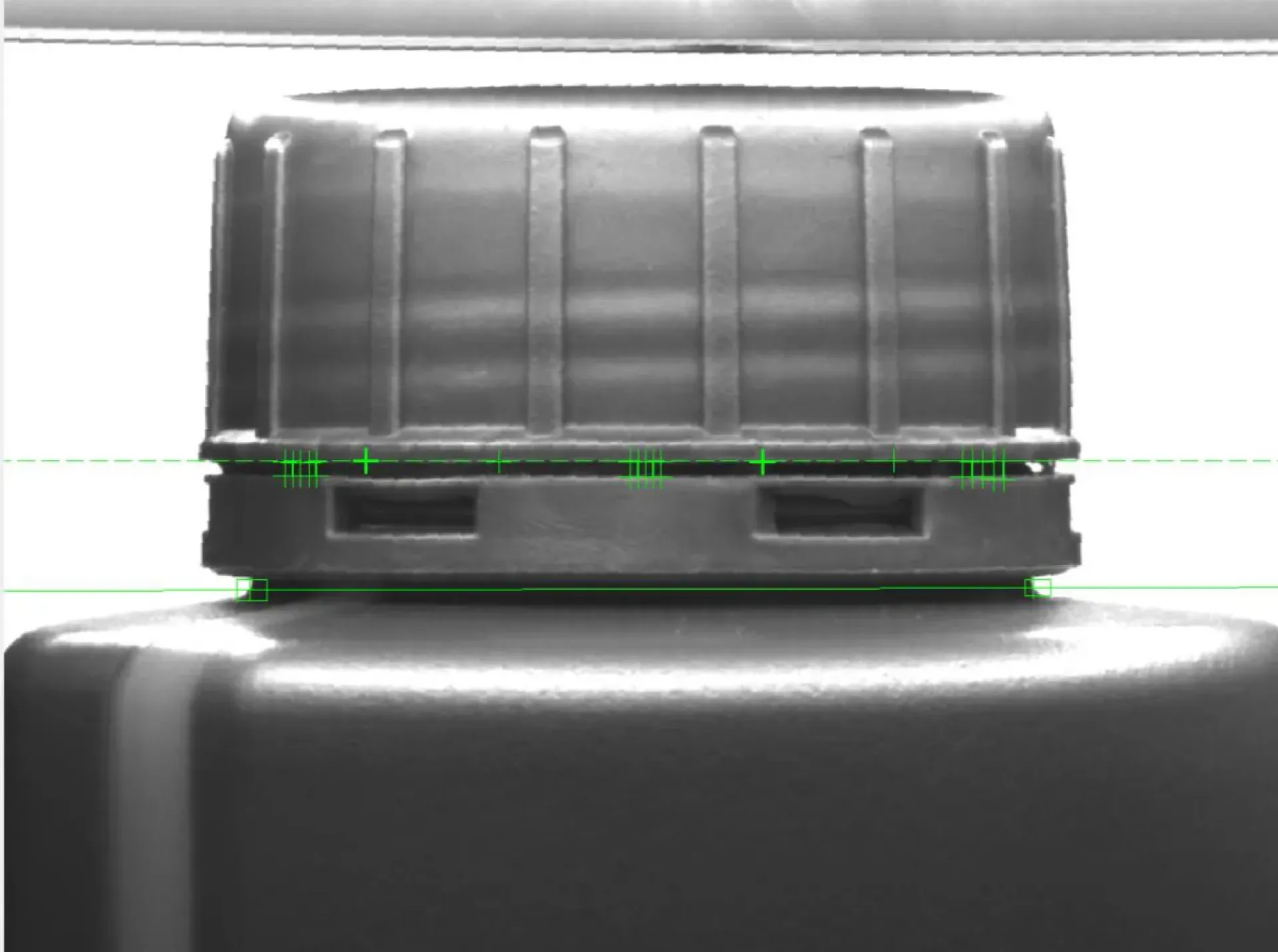

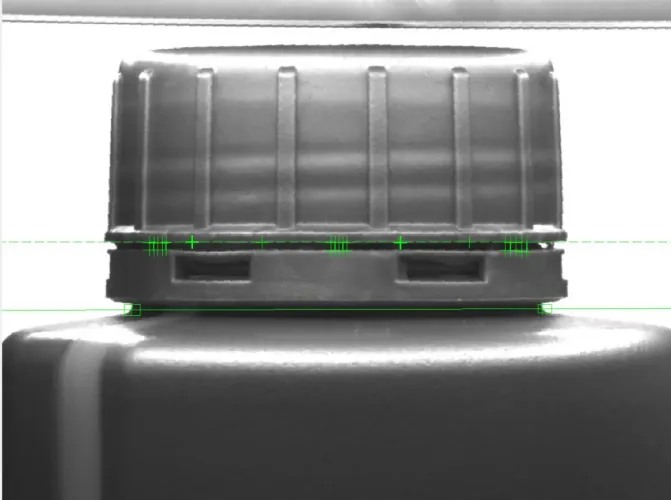

Correct seating of a cap on a bottle is essential for product safety, maintaining quality and preventing leakage. This system uses smart cameras that combine backlighting with direct SmartView lighting, enabling reliable detection and evaluation of correct cap position at high line speeds.

- A smart camera to ensure precise detection of caps on the bottle.

- SmartView backlighting – provides high contrast between the cap and its surroundings.

- Direct SmartView lighting – eliminates glare and ensures optimal conditions for inspection.

The main objective is automatic verification of the correct cap position on the bottle, whereby:

- The cap must be properly seated to prevent leakage or improper closure.

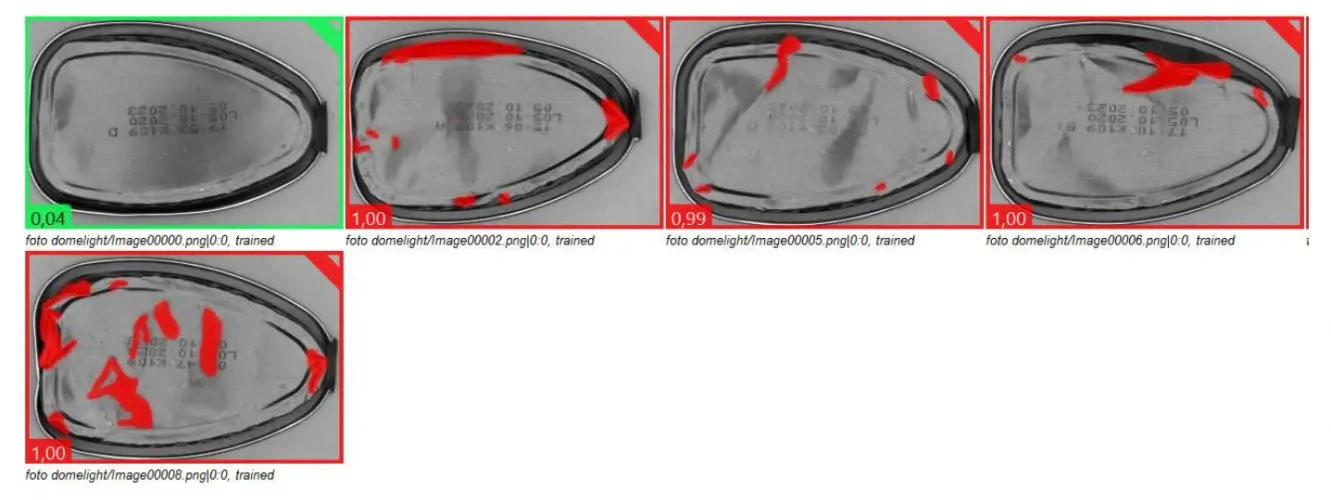

- Incorrectly placed caps must be quickly detected and flagged as nonconforming.

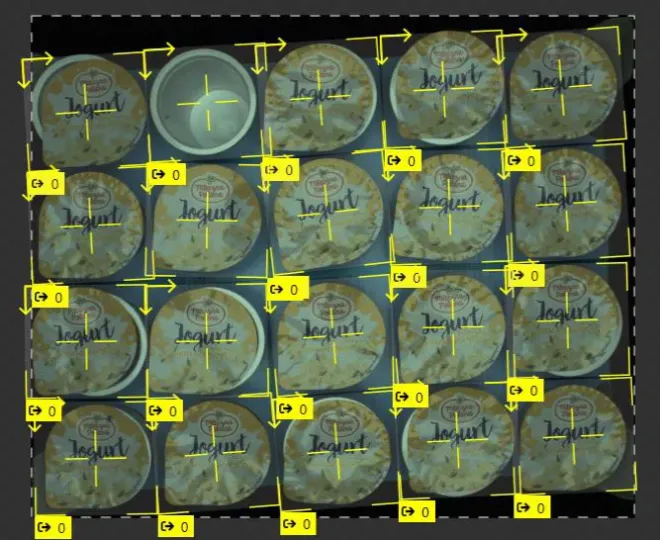

- The system must operate in real time so that production flow is not limited.

- Maintaining intense, homogeneous lighting at high line speeds.

- Selecting and combining camera software tools that allow fast detection and accurate evaluation of defective bottles.

- Eliminating disturbances such as glare and non-homogeneous lighting that could affect analysis accuracy.

- Use of a combination of SmartView backlighting and direct lighting providing consistent light conditions for the camera system.

- A 2D smart camera with high frame rate that enables immediate analysis of each bottle on the line.

- Optimization of software algorithms that detect incorrectly seated caps and enable their rejection from the process.

- The system enables reliable and continuous verification of proper cap seating, delivering:

- Accurate detection of correct cap position on every bottle.

- Fast evaluation of nonconforming pieces, which can be automatically removed from production.

- Seamless integration into the production line thanks to high speed and inspection accuracy.

- Cap positions are displayed in real time, enabling immediate evaluation.

- Incorrectly seated caps are highlighted for easy manual verification.

- Data are automatically stored, enabling retrospective analysis and quality trend tracking.

This system leverages long-standing experience in lighting, imaging and high-speed evaluation to enable efficient and accurate quality control of bottles.

Thanks to the intelligent combination of lighting, a camera system and software algorithms, maximum detection accuracy is ensured, minimizing production defects and optimizing the entire inspection process.