Proper sealing of packaging is essential in the food industry to maintain product quality, ensure safety and extend shelf life. Imperfect lid sealing can lead to leakage, contamination or product spoilage, resulting in rejection.

The proposed application uses a PC-based vision system with AI tools and SmartView lighting, enabling precise detection of imperfect sealing, its analysis and real-time defect classification.

- PC-based vision system with AI tools – advanced imaging technologies enabling fast detection of sealing defects.

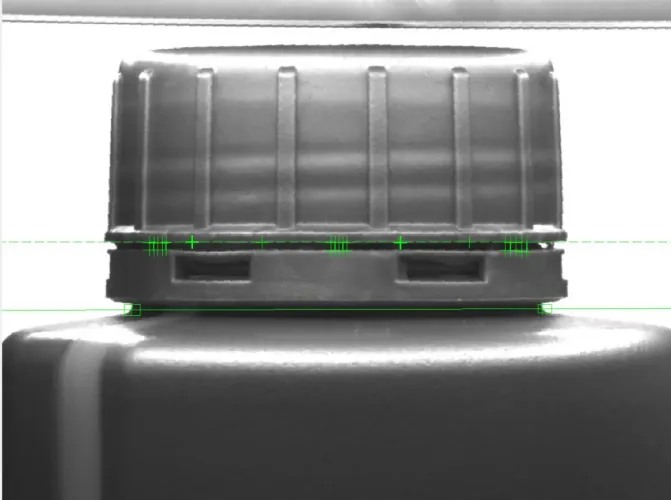

- SmartView lighting – polarized light ensuring minimal glare and optimized light homogeneity across the inspected area.

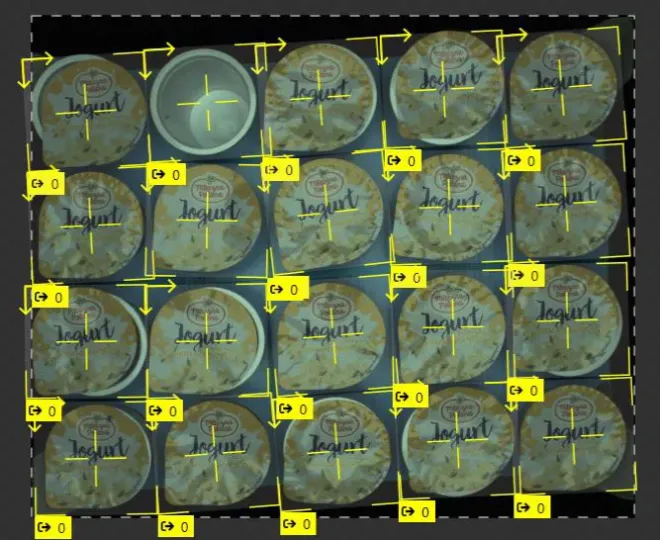

The system performs automatic verification of proper package sealing, whereby:

- It detects imperfect lid sealing, which can occur anywhere on the package.

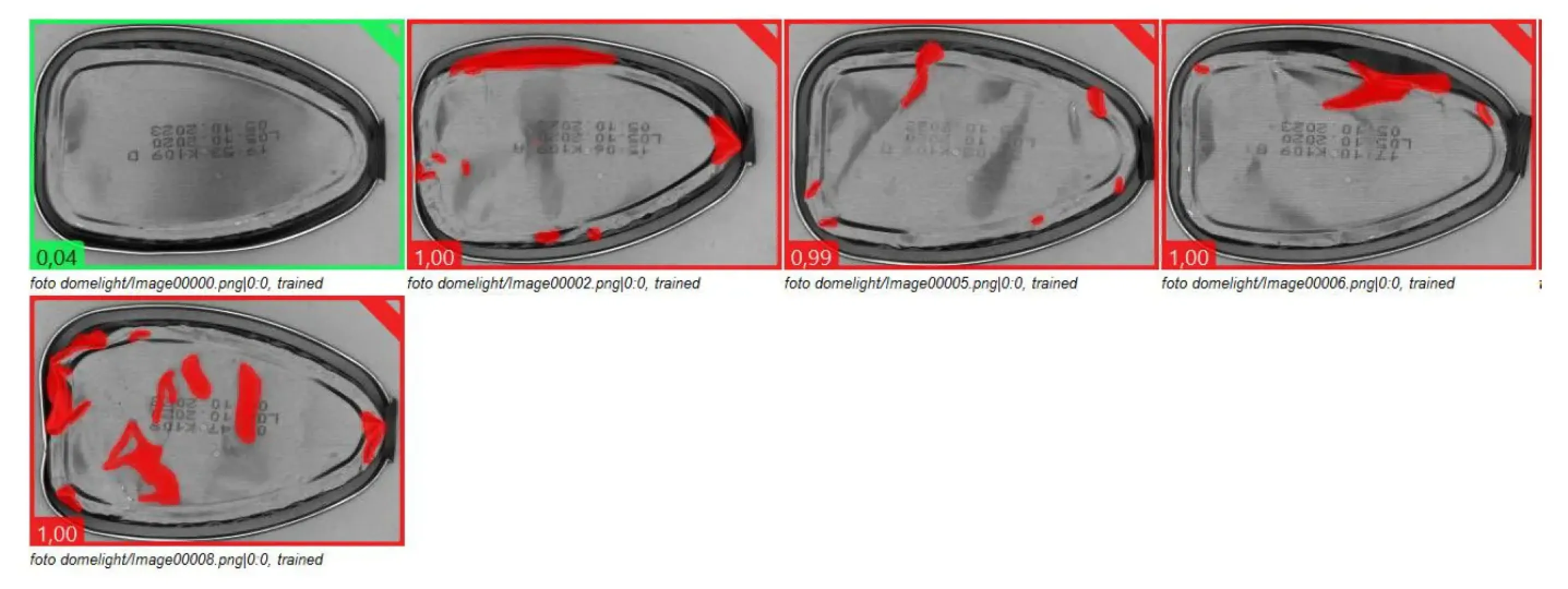

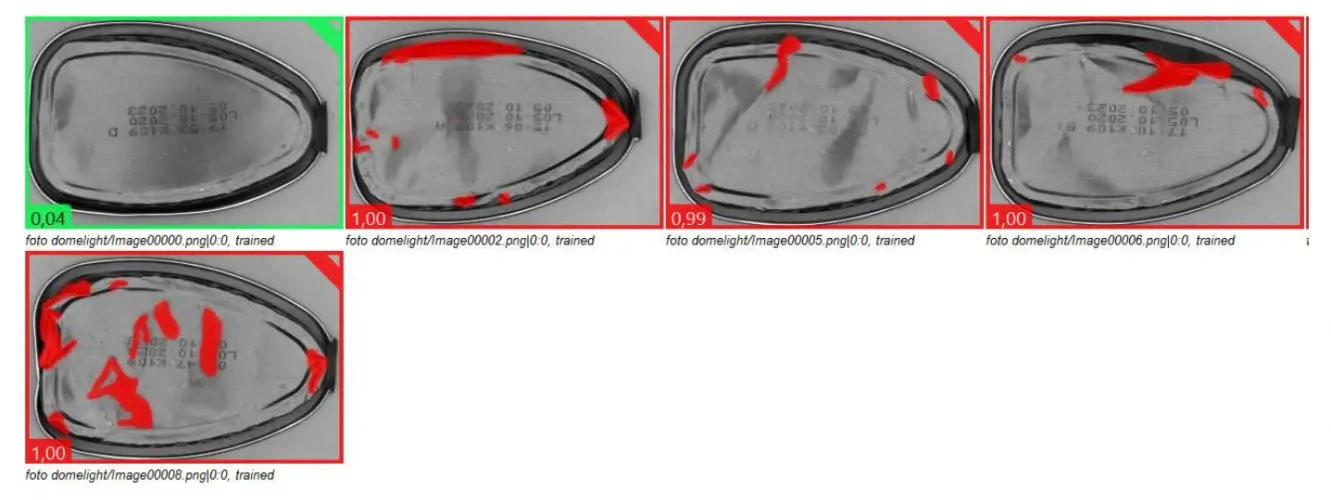

- It evaluates the size and shape of the defective joint to classify different sealing defects.

- It operates at high speed so inspection does not limit production.

- Ensuring consistent, effective lighting that can illuminate a large area without disturbing effects.

- Elimination of glare using polarized lighting to minimize detection errors.

- Various sizes and shapes of defective joints – AI algorithms must identify a wide spectrum of defects.

- High detection speed that must be synchronized with the production line.

- SmartView lighting providing optimal conditions for camera inspection.

- PC-based vision system with AI tools leveraging machine learning to detect and classify imperfectly sealed packages.

- Optimization of software methods ensuring reliable detection even at high processing speeds.

- Reliable detection of imperfect lid sealing across the entire package.

- Identification of a wide spectrum of defective joints, from small leaks to significant deformations.

- Seamless integration into production thanks to high detection speed.

- Each package is analyzed and visualized, with defective areas clearly highlighted.

- Data are automatically stored, enabling retrospective analysis of production quality and optimization of the packing process.

This system leverages specialization in lighting for camera applications and PC-based vision, enabling precise, efficient and fast quality control of package sealing.

Thanks to the intelligent combination of lighting, the camera system and AI algorithms, maximum detection accuracy is ensured, minimizing production defects and optimizing the entire inspection process.