In the food industry, correct placement of lids on plastic cups is essential to ensure quality, protect the contents and guarantee product safety. To minimize production defects, an automated visual inspection solution was developed using SmartView lighting, a 2D camera head, an industrial PC and software with AI algorithms.

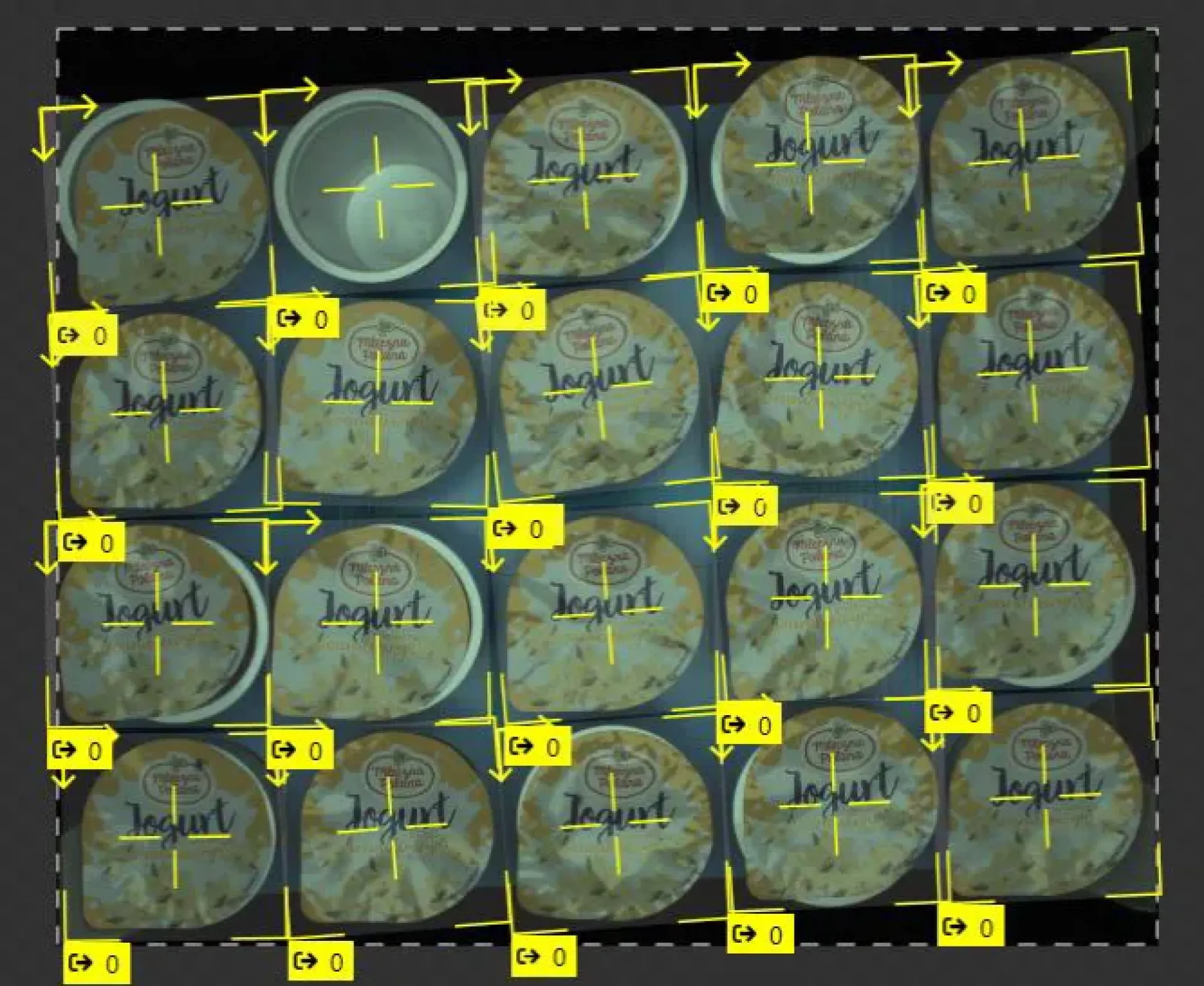

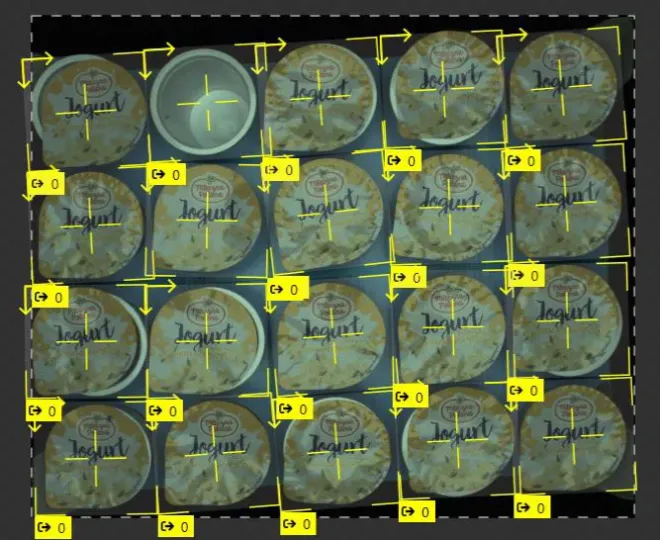

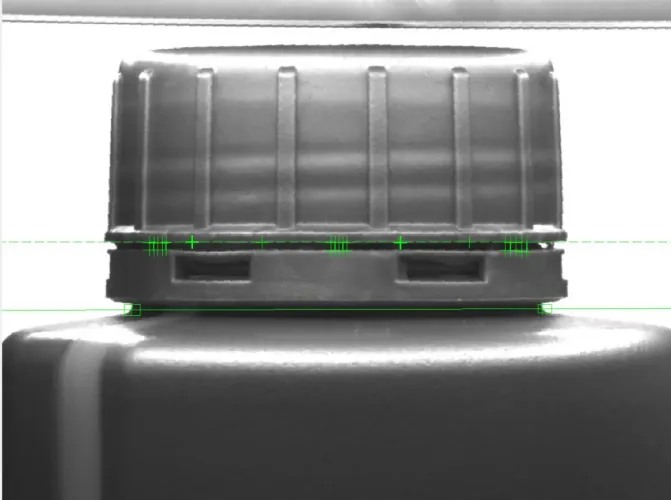

- SmartView lighting – homogeneous illumination with enough power for long working distances, minimizing glare.

- 2D camera head – captures lid presence.

- Industrial PC – enables fast and correct image evaluation.

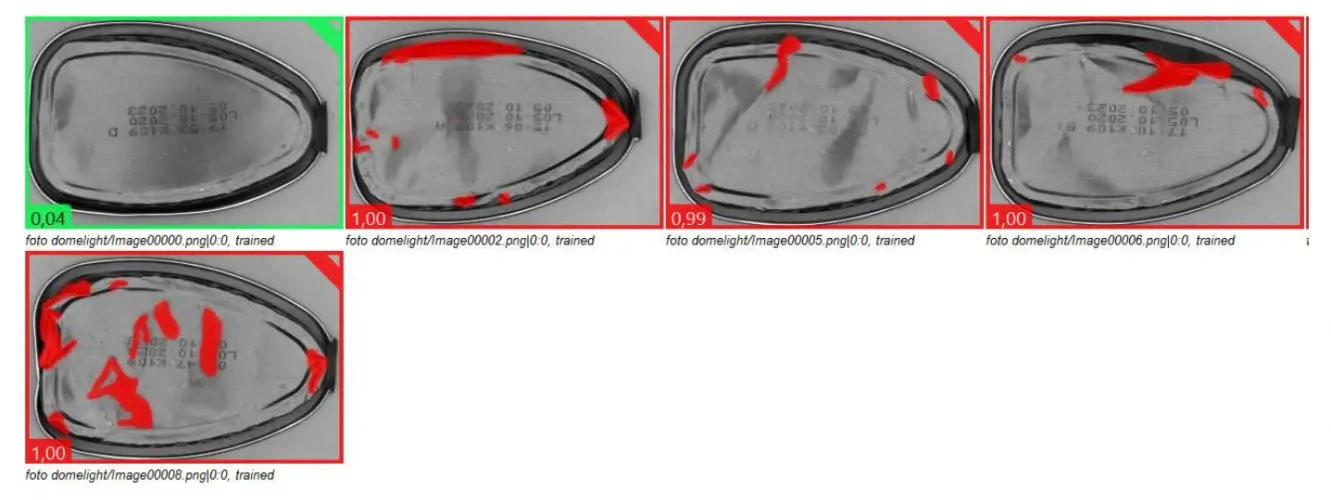

- Software with AI algorithms – recognizes lid mismatches, evaluates position and ensures 100% verification of proper seating.

The system performs automatic inspection of lids on plastic cups to ensure that:

- The lid is correctly seated on the cup without deformation or uneven positioning.

- Detection of an incorrectly placed lid is accurate and enables early problem detection.

- Processing speed matches the production process so inspection does not limit line throughput.

- Ensuring homogeneous scene illumination – some plastics are reflective and may affect image quality.

- Elimination of unwanted glare – light must be polarized so as not to affect detection accuracy.

- Data processing speed – lids must be checked in a short time interval.

- Large number of defective placement combinations – the system must recognize various types of incorrectly seated lids.

- Use of powerful homogeneous SmartView lighting with polarization to reduce unwanted glare.

- Industrial PC with optimized compute performance for fast image processing.

- Software with AI algorithms that learns to recognize correctly seated lids as well as various mismatch types.

- The system enables reliable verification of the lid’s presence and correct position on the cup.

- Incorrectly seated lids are automatically identified for rejection.

- Detection speed matches the production process, ensuring seamless integration into the line.

- Inspection results are visualized on the computer monitor.

- Each lid is analyzed and visualized by its state.

- Incorrectly seated lids are highlighted for easy identification.

- Data are logged, enabling trend analysis and retrospective quality checks.

This system uses advanced machine-vision lighting technologies to enable efficient, fast and accurate inspection of plastic cups. Thanks to AI algorithms, detection reliability increases and the system can recognize even complex lid seating errors that traditional methods might miss.

This solution minimizes production defects, ensures product quality and optimizes the entire manufacturing process.