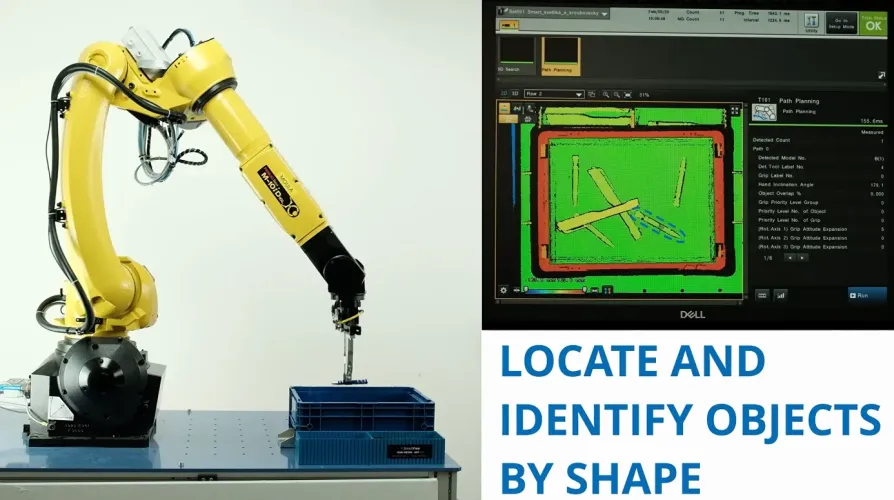

Automated tire palletizing requires precise control of their placement to prevent mechanical damage to the gripper and to ensure safe handling. This system uses a 3D head with a projector in combination with a robotic arm, enabling fast and reliable detection of incorrectly placed tires during palletizing.

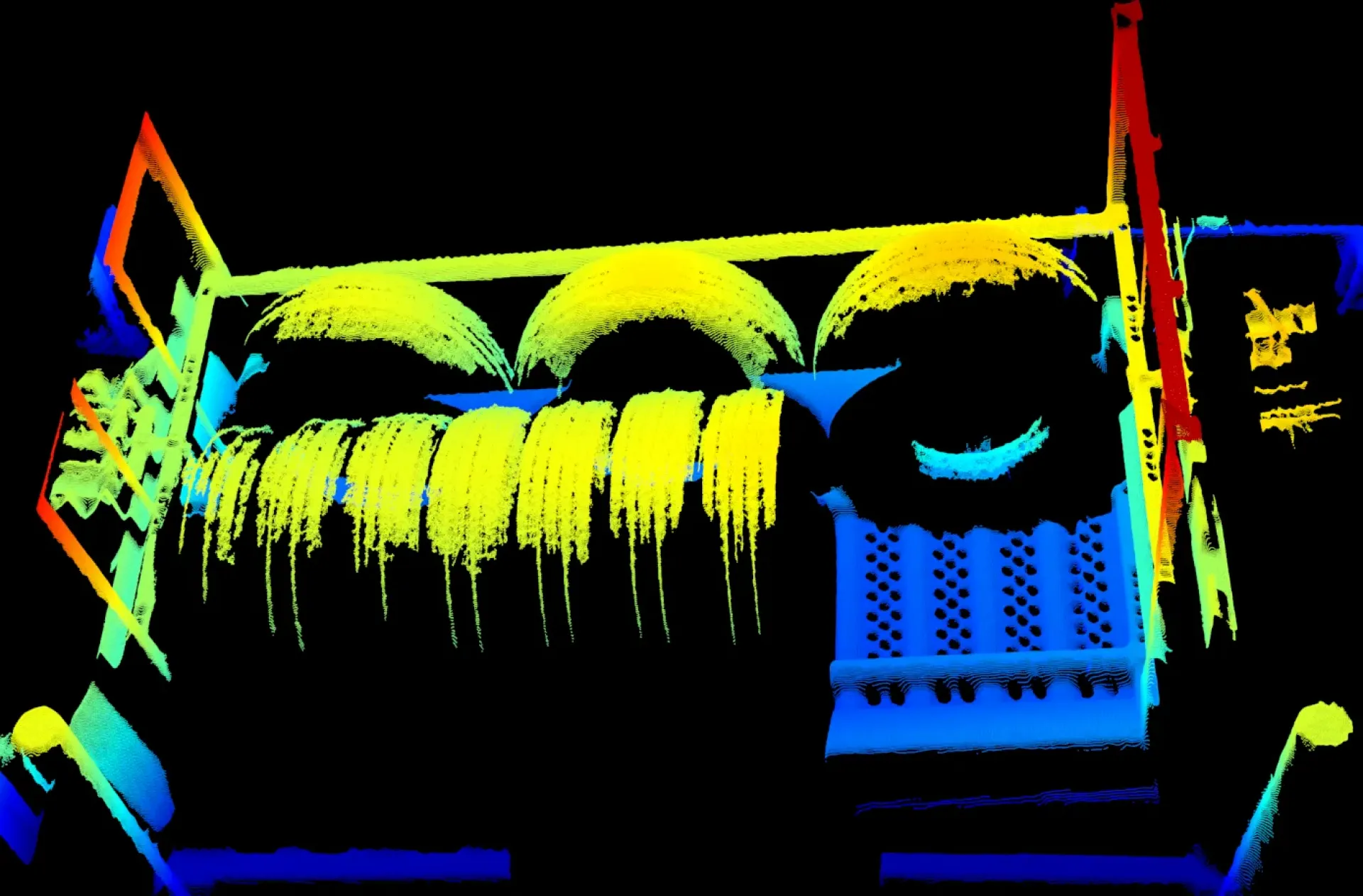

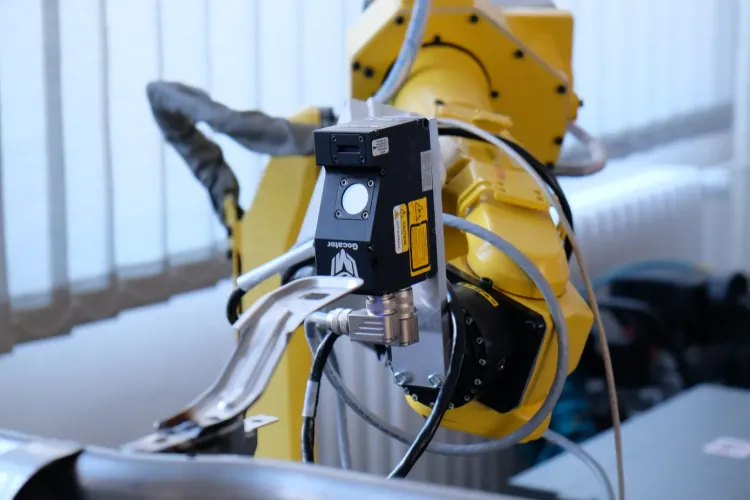

- 3D head with a pattern projector – enables scanning of large areas from long distances and accurate position identification of tires.

- A robotic arm – manipulates tires based on the analyzed data.

The system must detect incorrectly placed tires during palletizing with the aim to:

- Protect the gripper from damage that may occur when the last tire is placed incorrectly.

- Ensure sufficient space for the next tire to be seated correctly, eliminating the risk of deformation and gripper overload.

- Automatically stop the robot if a mismatch is detected and use signaling to call an operator for manual intervention.

- Scanning a large area from a long distance – sufficient resolution and measurement accuracy must be ensured.

- Accurate identification of incorrectly seated tires – deviations can be small but have a big impact on the process.

- Calibration of the robotic arm and 3D head – optimal settings are required for accurate detection.

- Cycle time adherence – inspection must be real-time without disrupting production.

- Communication with the master system – outputs from the detection system must be compatible with palletizing control units.

- Use of a powerful 3D head that enables accurate scanning of large areas and evaluation of tire position.

- Optimization of collision-state handling to minimize contact with tires placed out of position.

- Integration of the detection system with the master control system, enabling automatic stopping of the robot and operator alert in case of mismatch.

- Continuous verification of correct tire placement on the pallet.

- Prevention of gripper damage thanks to early detection of incorrect states.

- Automatic process stop on mismatch detection, eliminating the risk of production issues.

- Graphical display of tire seating on the pallet with color highlighting of incorrect placement.

- Automatic identification of slipped tires, enabling a quick operator response.

- Data storage in the system for trend monitoring and production issue analysis.

This system uses modern technologies to detect inconsistencies in automated palletizing, enabling efficient, accurate and safe handling of tires.

Thanks to specialization in robot calibration and 3D scanning, a highly reliable application has been created that helps minimize production defects and ensures palletizing quality.