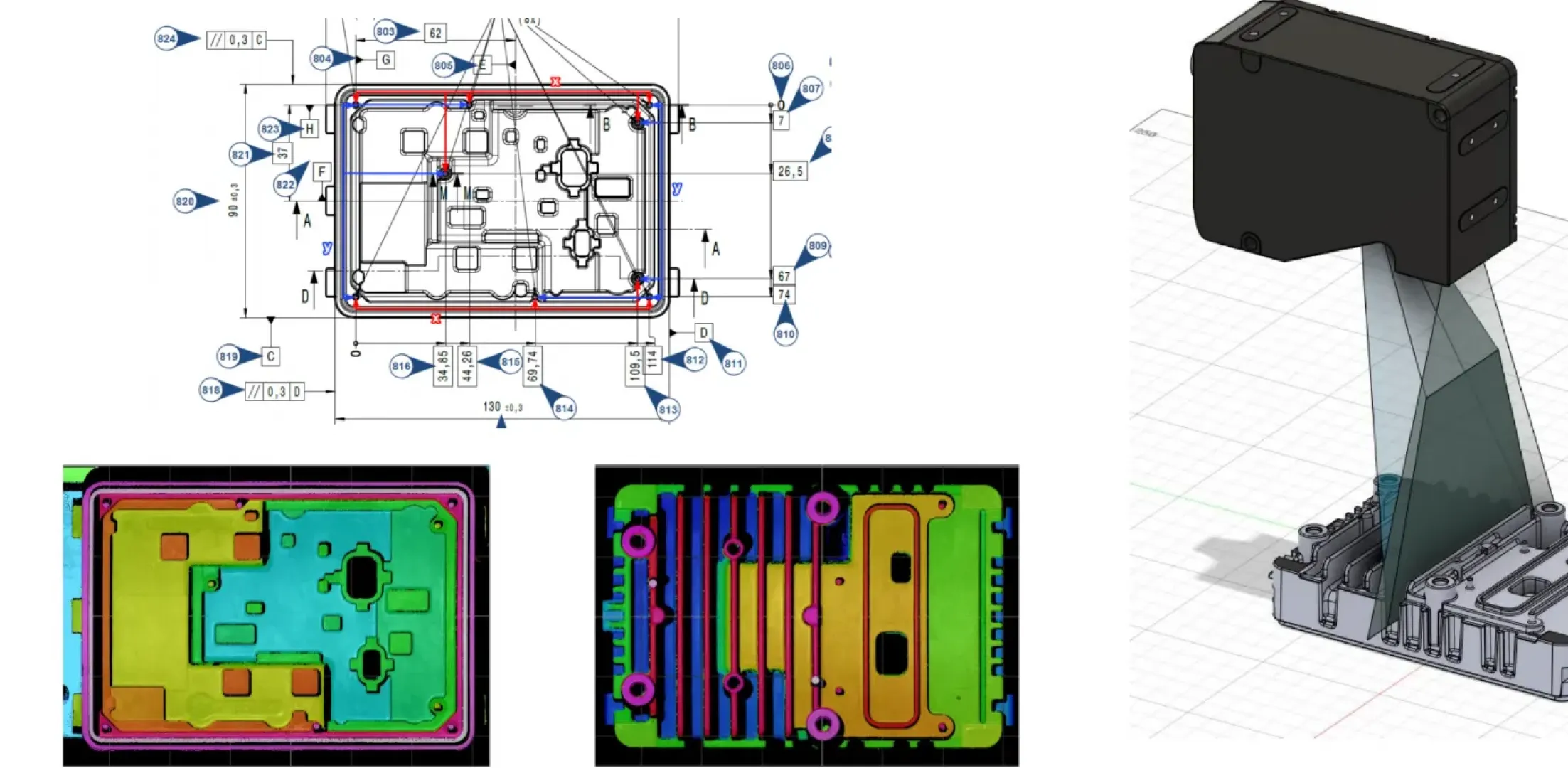

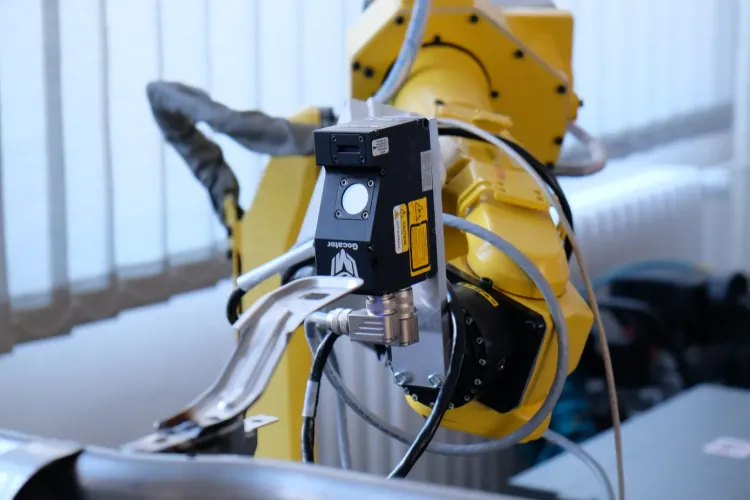

In industrial production the precise measurement of pins on a duralumin casting is crucial to ensure correct assembly and the functionality of the final product. This system uses a 3D triangulation profilometer mounted on a linear axis with an electric drive, enabling highly accurate and efficient inspection of pin presence and their misalignment.

- 3D triangulation profilometer – an optical device for detailed analysis of pin positions.

- A linear axis with an electric drive – ensures stable and smooth motion of the measuring unit along the inspected part.

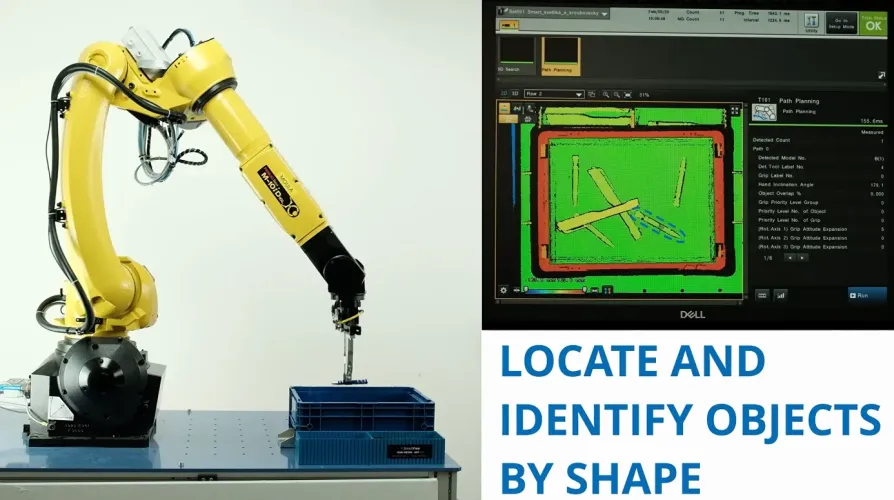

The system must measure the presence of pins on the duralumin casting and identify any misalignment against specified tolerances. The inspection process includes:

- Detection of all pins and their precise location on the casting.

- Evaluation of misalignment using the 3D profilometer.

- Comparison of measured values with defined tolerances to guarantee correct assembly.

- System calibration – required to ensure long-term measurement accuracy.

- Highly accurate misalignment measurement – small deviations can affect assembly and product function.

- Time constraints – inspection must be fast to avoid disturbing production.

Measurement is performed using optical inspection with a 3D triangulation head firmly mounted on the linear axis and moved along the duralumin casting. The measurement procedure includes:

- Capturing the 3D profile of pins on the casting.

- Automatic evaluation of deviations against reference data.

- Visualization and comparison of measured values with required specifications.

- Data storage for further analysis or long-term quality tracking.

The system enables reliable inspection of the presence of all pins on the casting and precise measurement of their misalignment. Results are presented digitally, where:

- Each pin is visualized in a graphical interpretation with numeric labels of the measured values.

- Comparison with required values allows instant identification of deviations.

- Data are logged and stored for further analysis or monitoring of long-term production quality.

- After measurement the results are displayed on the computer monitor.

- Pins are color-coded according to their status:

- Green – the pin meets the required values.

- Red – misalignment out of tolerance; inspection or adjustment needed.

- Measured values are compared with reference values, enabling quick quality decisions.

This 3D measurement system for pin misalignment uses advanced optical sensing and motion mechanism parameterization, providing a fast, precise and efficient solution for quality control of duralumin castings.

Thanks to specialization in 3D triangulation sensing, a highly reliable application has been created that significantly contributes to manufacturing process optimization.