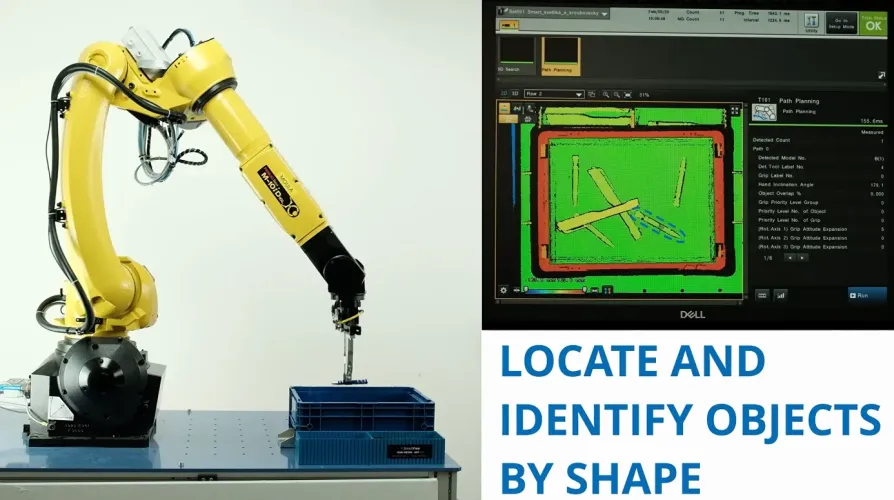

In the production process, robotized picking of parts from a blister plays a key role in automating handling, ensuring gripping accuracy and efficient line integration. This system uses a 3D head with a projector combined with a robotic arm, enabling precise part detection, gripping and minimization of handling errors.

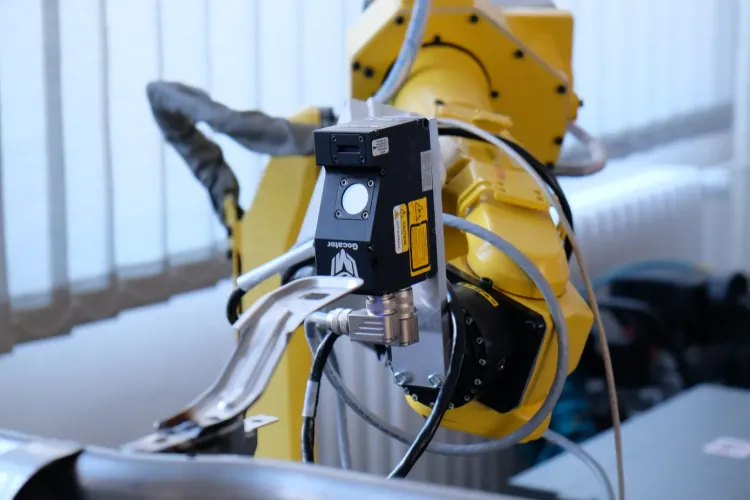

- 3D head with a pattern projector – enables part scanning and accurate identification of their position in the blister.

- A robotic arm – performs automated handling based on evaluated data and parameterization.

The system must ensure calibration and parameterization of the robot and the 3D head to achieve:

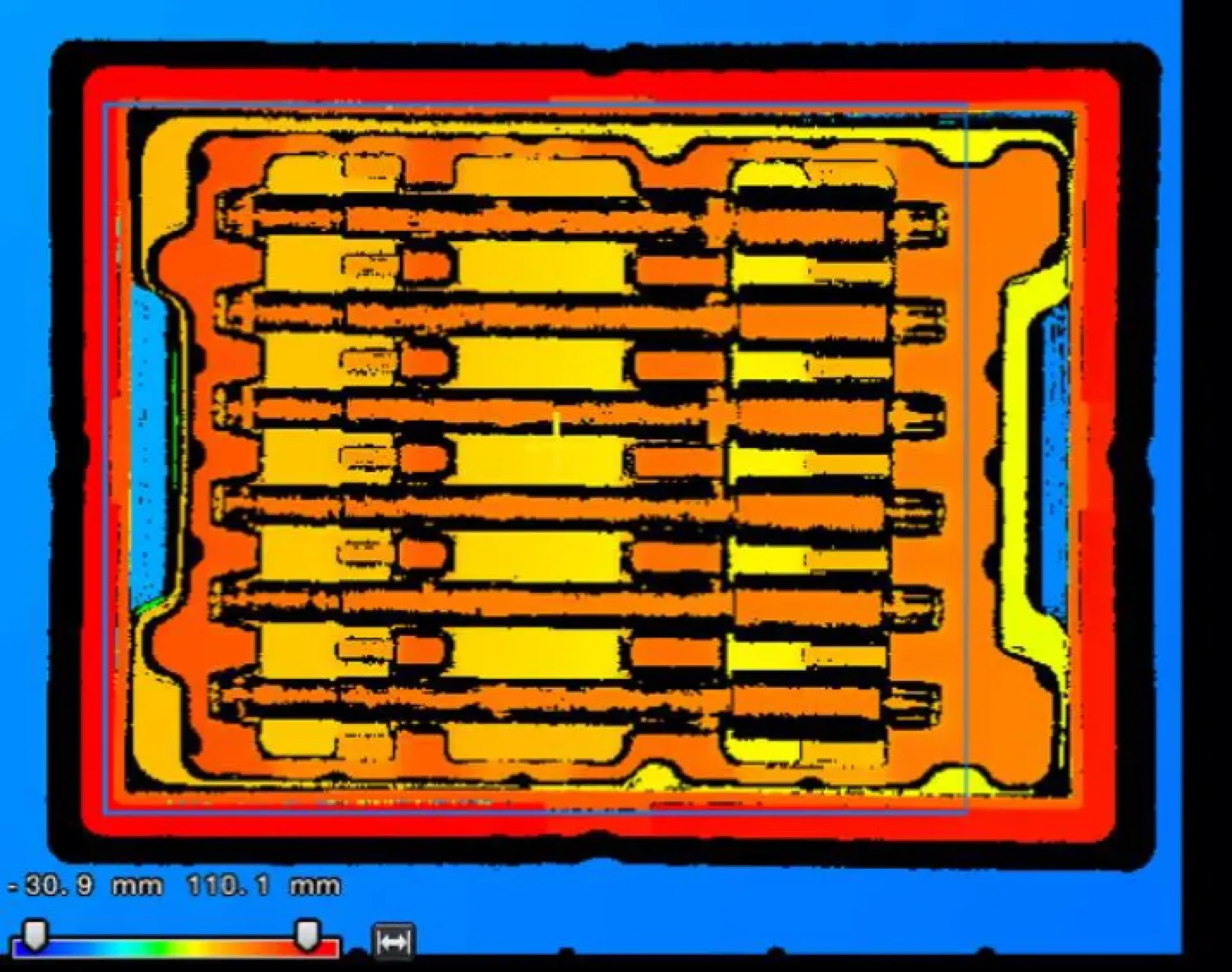

- Accurate detection of part positions in the blister using 3D scanning.

- Optimal gripping of parts to ensure safe handling without damage.

- Minimization of errors and increased handling speed to meet the line cycle time.

- Design of the gripper – the gripping mechanism must safely handle different part types.

- Optimization of the gripping point – selecting the correct point to avoid deformation or improper handling.

- Calibration of the robotic arm and 3D head – high accuracy and motion synchronization are required.

- Navigation of the robotic arm by a 3D head with projector, enabling precise localization of parts in the blister.

- Optimization of the gripping mechanism to safely handle different part types.

- Software parameterization to minimize errors, allowing system adaptation to current production needs.

- Reliable detection of parts in the blister.

- Optimized gripping preventing improper handling.

- Meeting the cycle time, enabling continuous line operation without disruption.

- Real-time display of proper gripping.

- Detection of problematic parts that are not suitably positioned.

- Data recording for retrospective verification and process optimization.

This system leverages long-standing experience in calibration and parameterization of 3D devices and robotic arms, enabling precise, efficient and safe automated part removal from blisters.

Thanks to the intelligent combination of 3D scanning, parameterization and advanced manipulation algorithms, maximum detection accuracy is ensured, minimizing errors in the picking process.