In manufacturing, surface defect detection on rubber seals is essential to ensure functionality, aesthetics and long service life. Any cracks, gouges, deformations or missing sections may affect assembly and performance of the final product, therefore early identification is necessary.

This system uses a smart camera with AI tools and SmartView lighting, enabling precise defect detection, classification and reliable analysis under varying production conditions.

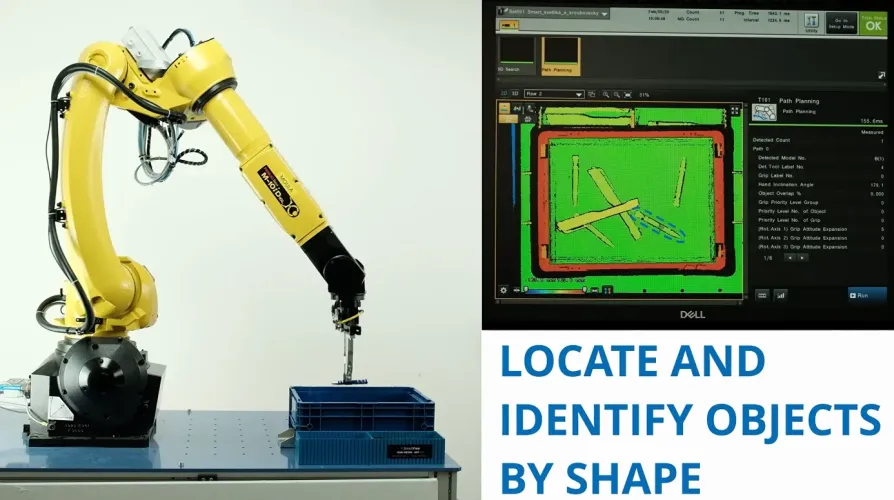

- A smart camera with AI tools – an advanced imaging system capable of detecting and classifying surface defects of rubber seals.

- SmartView lighting – provides homogeneous light conditions, minimizing glare and increasing contrast for better detection.

The system performs automatic inspection of surface defects, whereby:

- It identifies and recognizes different defect types such as cracks, gouges, deformations and missing sections.

- It ensures consistent lighting that allows recognition of defects on the entire area of the rubber seal.

- It operates in real time so inspection does not slow the production line.

- Consistent lighting – necessary to provide lighting that highlights defects and eliminates glare from the rubber seal.

- Defects can appear anywhere and in many forms – AI tools must recognize various types of damage on rubber parts.

- High detection speed – the system must analyze many parts in a short time.

- SmartView lighting providing optimal conditions for camera detection and minimizing disturbances.

- A smart camera with AI tools using machine-learning algorithms to analyze and classify defects.

- Use of software tools that allow system adaptation to specific production requirements.

- Reliable detection across the entire area of the rubber seal, providing complete product control.

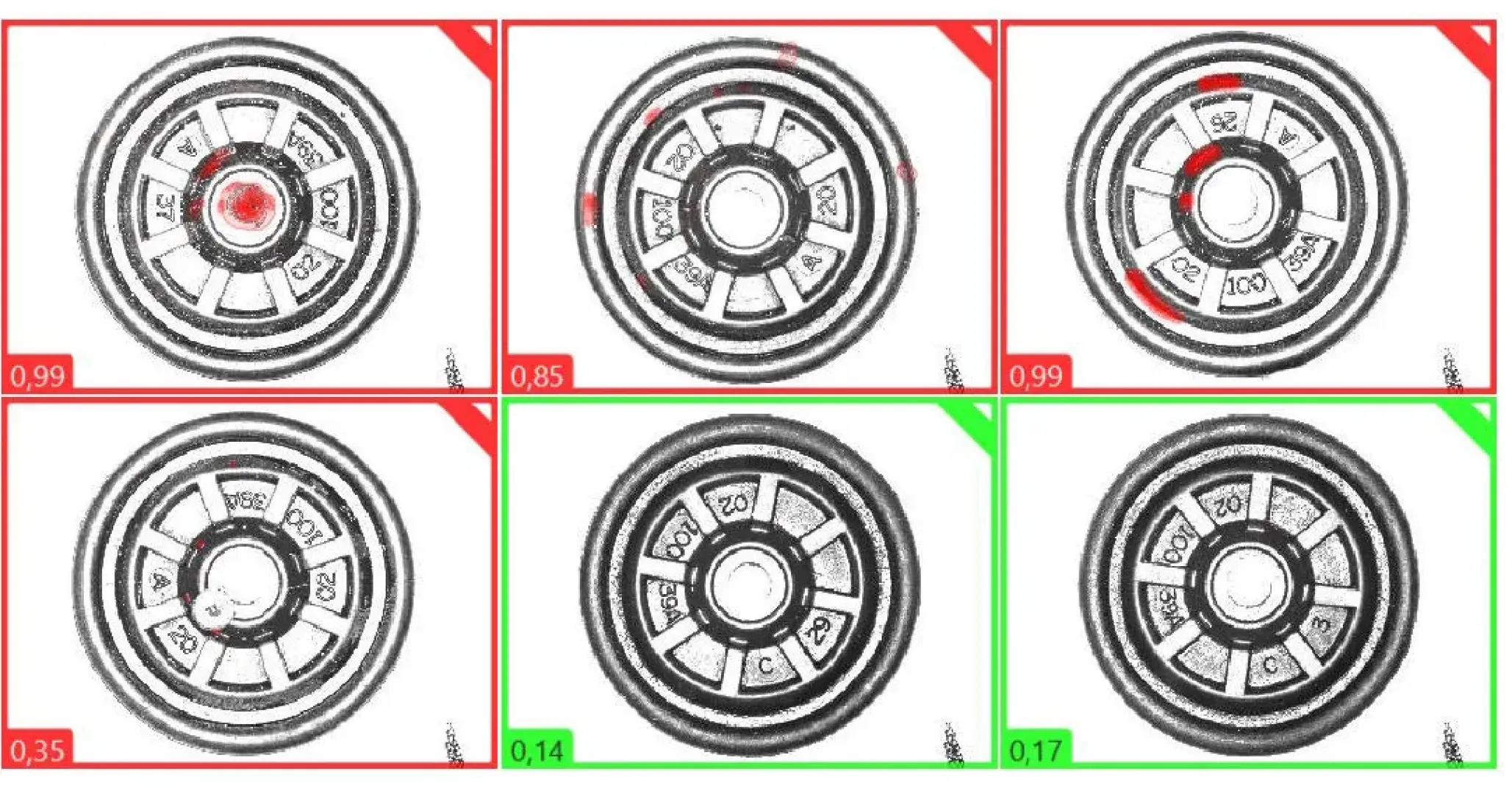

- Identification of a wide range of defects, across different sizes and shapes.

- Seamless integration into production thanks to high analysis speed.

- Each plastic part is analyzed and visualized with clear highlighting of defective areas.

- Defective parts are classified by damage type, enabling effective decisions about further processing.

- Data are automatically stored, enabling retrospective analysis of production quality.

This system leverages specialization in lighting for camera applications, enabling precise, efficient and fast quality control of plastic parts.

Thanks to the intelligent combination of lighting, the camera system and AI algorithms, maximum detection accuracy is ensured, minimizing production defects and optimizing the entire inspection process.