In food and industrial packaging, text inspection on labels and packages is crucial for correct product identification, proper marking and regulatory compliance. Any missing text or incorrect labeling can lead to mislabeling, affecting inventory management, customer experience or even product distribution.

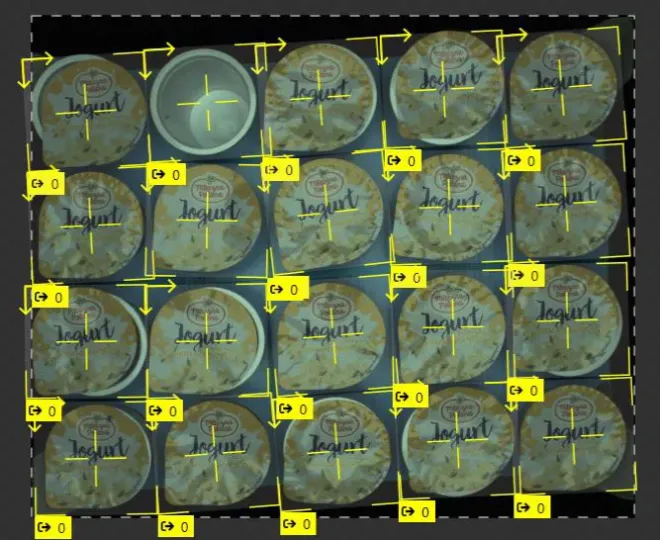

This system uses a camera sensor combined with SmartView lighting, enabling fast and reliable text inspection on packaging at high line speeds.

- A camera sensor – a compact imaging device for detecting and analyzing text on packaging.

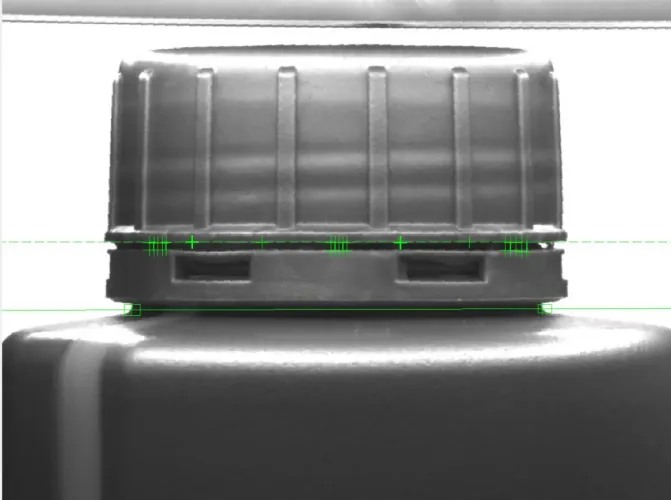

- SmartView lighting – provides homogeneous illumination with glare elimination, enabling clear recognition of text.

The system performs automatic text identification on every package with the aim to ensure:

- Detection and validation of text presence on each subsequent product at high line speed.

- Use of hardware that is sufficiently capable yet cost-optimized so planned budget limits are not exceeded.

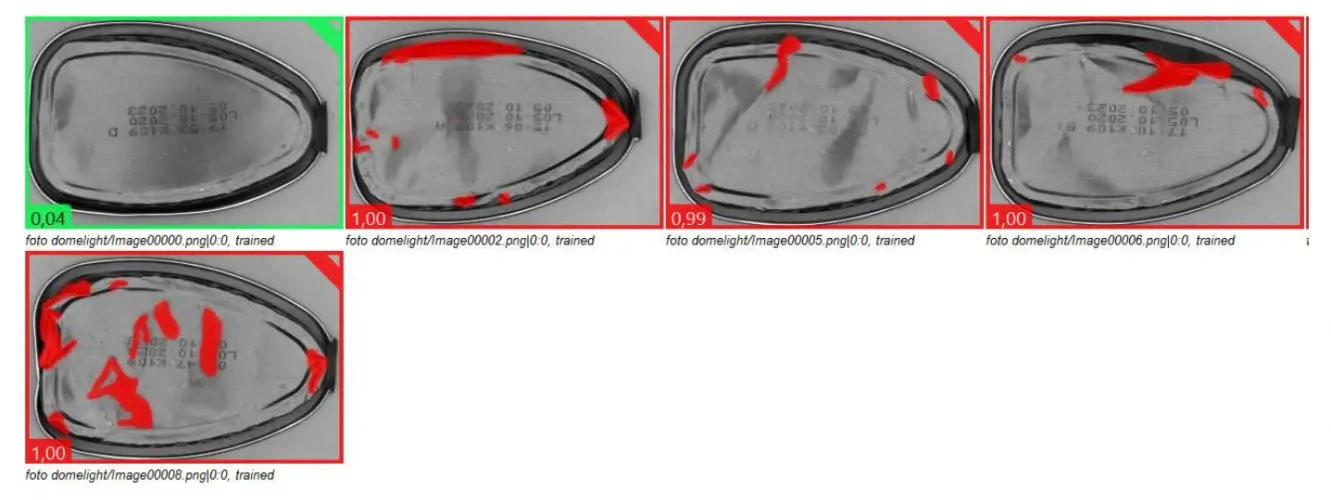

- Ability to retrain the system on different text, since each package has a different name.

- Ensuring consistent lighting that enables correct text detection on various packaging materials.

- Elimination of glare that may complicate recognition of printed text on reflective or irregular surfaces.

- Camera sensor setup to ensure accurate detection at high production speeds.

- Selection and combination of suitable software tools that enable fast detection.

- Use of SmartView lighting that eliminates unwanted glare and provides optimal conditions for camera inspection.

- A camera sensor with high frame rate that enables real-time text identification and validation.

- Software tools for text detection that allow retraining on new labels according to current production needs.

- Reliable identification and validation of text on every package.

- Easy retraining options, enabling flexibility when producing different products.

- Seamless integration into production thanks to high detection speed and optimized hardware.

- Display of correct text on the package, enabling easy identification of conforming products.

- Incorrectly labeled packages are visually highlighted to enable automatic rejection.

- Data are automatically stored, providing retrospective analysis of labeling quality during production.

This system leverages specialization in lighting for camera applications and fast inspection processing, enabling precise, efficient and fast text control on packaging.

Thanks to the intelligent combination of lighting, the camera system and software algorithms, maximum detection accuracy is ensured, minimizing labeling errors and optimizing the entire inspection process.